Beyond Aero has completed its first wind tunnel test campaign, validating key aerodynamic aspects of its hydrogen-fueled business jet.

The Toulouse, France-based startup is developing its six-passenger BYA-1 hydrogen-electric CS23 light jet to enter service by 2030. The aircraft has a planned range of 1,500km (930 miles) and a cruise speed of 573 km/h (356mph).

The BYA-1 aircraft uses a low-temperature proton exchange membrane fuel cell stack with a capacity of 2.4MW to power two electric engines. Gaseous hydrogen will be stored at 700-bar in tanks integrated within the wingbox structure.

Beyond Aero completed a series of full-power ground tests with its fuel cell power system last October

Wind tunnel test campaign

The test campaign was conducted over five weeks during autumn 2025 at the German-Dutch Wind Tunnels Low-Speed Facility in Marknesse, Holland.

The test campaign focused on validating the aerodynamics – including performance, stability and control – of the BYA-1 design, which integrates gaseous hydrogen tanks outside of the fuselage.

Beyond Aero said data from the wind tunnel test campaign is a key step towards experimentally validating the BYA-1’s aerodynamics, and a major milestone towards concluding the Preliminary Design phase.

Validating a hydrogen-driven aerodynamic architecture

Beyond Aero is integrating its gaseous hydrogen tanks externally for safety reasons. However, this creates complex aerodynamic interaction zones at the wing-fuselage junction and wingtips – regions where even minor design changes can significantly influence lift, drag, and stability.

So far, only computer simulation and modeling has been performed to validate BYA-1’s aerodynamic design. Although these provide confidence, the design and interactions around the wing-fuselage junction and wingtips cannot be fully de-risked through computation alone.

The objective of the wind tunnel testing campaign was therefore confirm that the design, which includes the hydrogen storage, behaves in a stable, predictable, and controllable manner across the intended flight envelope, as well as optimize performance.

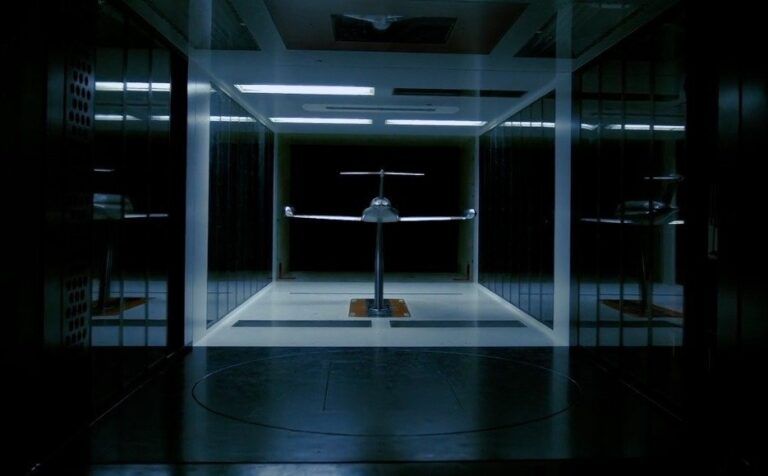

A scaled model provides experimental proof

The wind tunnel tests used a 1:8 scale model and generated more than 60,000 data points. The campaign investigated aircraft performance, stability, and control across a range of configurations, including multiple flap settings, control surface deflections, and off-nominal conditions such as high angles of attack, sideslip, up to deep stall. Testing was conducted at speeds up to 80 m/s (288 km/h).

Measurements combined global aerodynamic forces and moments, captured via a six-component balance, with detailed local pressure data from more than 230 pressure taps distributed across the model.

The resulting dataset has enabled robust correlation with numerical simulations and provided high-fidelity experimental reference data for the aircraft’s external aerodynamics.

According to Beyond Aero, its engineers have used AI to accelerate the development of tools that correlate and visualize large experimental and numerical datasets, allowing them to optimize conventional aerodynamic validation processes. The tools helped engineers identify trends, assess sensitivities, and converge more efficiently.

Validation of primary aerodynamics

Data from the wind tunnel tests confirm the robustness of the BYA-1’s aerodynamic design. Beyond validating numerical models, which will be used for further computer simulation, it confirmed the primary aerodynamic assumptions associated with the hydrogen architecture, enabled detailed characterization of critical interaction zones, and reduced residual aerodynamic uncertainty ahead of a design freeze and subsequent development phases.

Delphine Bonnaud, head of aerodynamics at Beyond Aero said, “The development of a hydrogen-electric aircraft requires precise aerodynamic design. The strong correlation between experimental results and numerical simulations in the linear domain gives us a solid validation of our numerical process.

“This wind tunnel campaign delivered high-quality experimental data that directly supports our aerodynamic models and design decisions. It contributes to the validation of the aircraft’s Preliminary Design Review by providing a solid experimental reference for the external aerodynamics,” said Luiz Oliveira, chief of engineering at Beyond Aero.