GRAS Sound & Vibration is represented through subsidiaries and distributors in more than 40 countries and is part of Axiometrix Solutions, a leading test solutions provider comprised of globally recognized measurement brands.

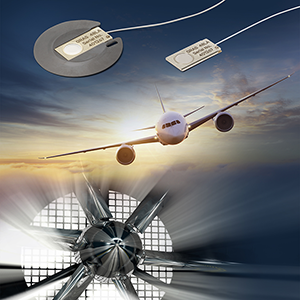

UTP - The World’s Thinnest Condenser Microphones

The main focus of wind noise testing in the aerospace industry are measurements in boundary layers. Research is often aimed at separating the acoustic signal from the flow-induced turbulent noise. Purposes span quantifying the amount of sound power radiated from a structure, over sound source localization using an array of microphones to quantifying the turbulent stresses to which a structure is subjected.

The UTP (Ultra-thin Precision) microphones from GRAS is a suite of highly precise and reliable surface-mounted condenser microphones with all the expected quality and precision of a classical measurement microphone aimed at boundary-layer measurements. The very low profiles of just 1 mm (0.04 inches) reduce turbulence influence dramatically and are expected to change aeroacoustic testing in wind tunnels and in flight fundamentally.

Computational Fluid Dynamics (CFD) modeling is an integral part in the design of vehicles that move in airflow. However, airflow and turbulence is difficult to simulate and predict realistically. When measuring turbulent boundary-layer noise, flush-mounted pressure sensors and microphones are often used in order not to disturb the airflow or add additional turbulence. However, this often requires destructing the device under test. Where destructive testing is not possible, surface-mounted sensors are used with the risk of contaminating the results with self-induced turbulent noise due to the profile height of the sensor.

Only very small, thin and aerodynamically correctly shaped sensors can overcome these challenges – validating the modeling and supplying the additional measurement data needed. The form factor and easy mounting of the UTP microphones make them suitable for in-situ boundary-layer testing, when neutral impact and high precision is important.

The UTP family of microphones has been developed in close cooperation with the industry, and has been extensively tested for aerospace as well as automotive applications. The UTP microphones are suitable for test applications where traditional sensors are difficult to mount and where the boundary layer is thin, for example at the belly fairing, the karman or the cockpit window.

A version of the UTP microphone has been designed for wind tunnel testing of components or scale models. This version has a frequency range of up to 70 kHz and a noise floor of only 54 dB. All microphones are calibrated to international standards at the GRAS Headquarters in Denmark. The UTP microphones also be in-situ verified using a handheld calibrator with an adapter for sensitivity verification developed for planar or curved surfaces.

The UTP microphones beat any flush- or surface-mounted microphone on the market—superior performance, unbeatable price, fast and repeatable mounting— and should be a first choice for cost-effective, high-precision testing of any boundary-layer application. In essence, the UTP microphones are flat, fast and precise, a revolutionary new design that has made it possible to combine a ¼” condenser microphone with a form factor that makes it the world’s thinnest measurement microphone.