Researchers in the US have developed a dynamic polymer material that can heal itself after being punctured by switching between solid and liquid states, potentially offering protection for spacecraft and other applications.

Materials scientists at Texas A&M University have developed the polymer, which they say has self-healing properties never before observed. When struck by a high-speed projectile, the material stretches dramatically, allowing the projectile to pass through while creating a hole significantly smaller than the projectile itself.

“This is the first time a material at any scale has displayed this behavior,” said Svetlana Sukhishvili, a professor in the department of materials science and engineering, who developed the polymer film with colleague Edwin Thomas and then-graduate student Zhen Sang. Their findings appeared in the March/April issue of Materials Today.

The polymer belongs to a class of materials called Covalent Adaptative Networks (CANs) and is specifically a Diels-Adler Polymer (DAP), named for its dynamic covalent bond networks that can break and reform. While other Diels-Adler networks exist, this particular DAP’s chemistry, topology and self-healing quality are novel.

When impacted by a high-speed projectile, the solid polymer film melts, absorbing much of the kinetic energy generated by the projectile. This causes the film to stretch and liquify as the projectile continues through, finally piercing the film. Once penetrated, the polymer rapidly cools, its covalent bonds reform, and it returns to its solid state with only a tiny hole remaining.

“A major goal of our work was to see if we could simultaneously provide a material that would absorb a lot of kinetic energy per unit target mass from the high-speed projectile and be capable of very rapid healing of the punctured region,” Thomas said. “We wanted the post-impact material to still be capable of performing its intended function, such as carrying air or liquids and remaining sealed against the loss of such fluids.”

The DAP structure consists of long polymer chains containing double carbon bonds that break when severe strain and heat are applied, but quickly reform when cooled.

“Think of the long polymer chains in the fabric as being like a bowl of Ramen noodle soup,” said Sang, who worked on this project for his doctoral research and is first author on the paper. “You can stir it with chopsticks, then freeze it. When you unfreeze it, you can stir it, then refreeze. It will have the same ingredients as before, just in a slightly different appearance.”

During testing, the research team used laser-induced projectile impact testing (LIPIT) to launch a silica projectile 3.7 micrometers in diameter at a thin layer of the polymer (75 to 435 nanometers). They recorded the impact with an ultrahigh-speed camera and analyzed the results using scanning electron microscopy, laser scanning confocal microscopy and infrared nano spectrometry.

Initially, Sang could not find any holes in the targeted polymer, raising questions about the experiment. Only when examining the sample under the infrared nano spectrometer, which combines chemical analysis with high-scale resolution, could he detect the tiny perforations.

This phenomenon cannot yet be replicated at the macro level because the strain rate during perforation of a very thin target material under impact is drastically higher at the nanoscale.

“If this strain rate is really high, materials often have unexpected behavior that people don’t usually see under normal circumstances,” Sang said. “With the LIPIT apparatus that we’re using, we’re talking about a strain rate many orders of magnitude higher than for conventional scale bullets and targets. At that perspective, materials behave very differently.”

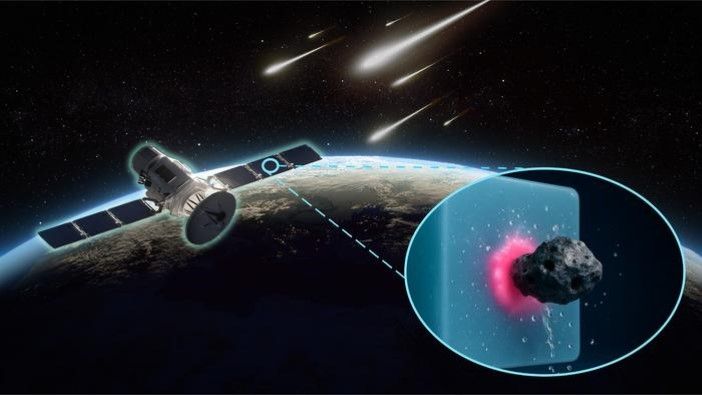

Potential applications include making spacecraft windows more resilient to micrometeoroid impacts. Space vehicles frequently encounter micrometeoroids traveling at speeds of 10 km/s, which can create visible holes in windows. A window manufactured with a layer of this polymer could potentially sustain damage even smaller than the meteoroid itself.

Thomas and Sukhishvili are continuing their research with different polymer compositions, temperatures and stress-responses. They envision designing DAPs that could absorb kinetic energy by breaking bonds that rapidly reform, forcing a projectile to break these bonds multiple times before the material ultimately heals itself.

“To date, no material has the requisite time response to deform, break, reform – and then deform, break and reform again during the sub-microsecond interval of a ballistic event,” Thomas said.

The research team included materials science doctoral student Hongkyu Eoh, former postdoctoral researchers Kailu Xiao, Wenpeng Shan and Jinho Hyon, and Dmitry Kurouski, associate professor in the department of biochemistry and biophysics at Texas A&M.