The space environment around Earth is becoming increasingly hazardous as millions of debris fragments threaten operational satellites and future missions. While the problem is growing exponentially, technical solutions are emerging that should help preserve orbital access for future generations.

The scale of the debris challenge has reached critical proportions and current tracking capabilities revealing only a fraction of the hazardous material orbiting Earth. However, technologies such as millimeter-wave radar and autonomous robotic systems have the potential to both accurately quantify the threat and then actively remove it.

ASSESSING THE DEBRIS PROBLEM

The orbital environment has deteriorated significantly beyond what space agencies consider manageable for routine operations. Earlier this year, the European Space sweepers Agency (ESA) launched a campaign highlighting the dangers it poses and how it could disrupt the growth of the space industry.

Today, tracking systems identify about 40,000 debris objects larger than a smartphone in orbit. But this represents only the visible portion of a much larger debris field. Speaking at the Ninth European Space Debris Conference, in Bonn, Germany during April Holger Krag, head of the space safety programme office at the ESA said, “1.1 million is our estimate for everything above the size of a cherry – 1cm. We cannot see this debris anymore from ground, but there are good model-based assumptions. There are 130 million objects out there larger than 1mm.”

The impact on operational missions has become measurable and severe. Earth observation satellites routinely lose operational time due to collision avoidance maneuvers, with ESA analyses indicating that the situation will worsen dramatically without intervention.

“For an Earth observation mission, every day we have to do a collision avoidance maneuver we lose data, because we cannot perform the mission during the maneuver,” Krag says.

“When we extrapolate the trend we are on now with doing nothing, we end up in a situation where our annual calendar is full of maneuvers. We will hardly have any time left to do the mission.”

Real-world impacts demonstrate the threat posed by millimeter-scale debris. Ten years ago, ESA’s Sentinel 1A environmental satellite was struck by a 2mm fragment that generated additional trackable debris. The debris from that impact subsequently triggered collision alerts with other spacecraft years later – evidence that even small debris can create much larger problems over time.

The fundamental challenge lies in the exponential growth pattern of space debris. The ESA reports that an average of 10 fragmentation events occur per year. Approximately 60% of current space objects are a result of failed passivation or explosions rather than operational deployments.

DEBRIS MONITORING

Advanced radar technologies offer a solution for understanding and quantifying the small debris environment that poses the greatest operational threat. Millimeter-wave radar systems developed for space applications can detect debris down to the millimeter scale, providing the data necessary to model and predict debris field evolution.

Richard Jacklin, commercial lead at Cambridge, UK-based engineering firm Plextek, explains the approach: “At the moment, ESA and NASA only have theoretical models for this type of debris. They don’t have enough data to give them an accurate picture of what the debris fields look like at different altitudes in Low Earth Orbit.”

Millimeter-wave offers several advantages over traditional radar frequencies for detecting small debris. “To be able to see a millimeter-sized piece of debris, you need a very short wavelength. You can’t use the lower frequencies at X band or C band or the more traditional radar bands,” Jacklin says.

Solid-state, millimeter-wave detection systems can be packaged into compact and low power payloads, suitable for deployment on operational satellites. The systems, which are around the size of a smartphone and consume less than 20W peak power could be deployed across satellite constellations to establish comprehensive debris mapping capabilities.

If debris fields can be measured, mapped and tracked, they can then be more efficiently avoided. Models suggest fields are distributed unevenly around the Earth. Understanding the distributions would enable mission planners to avoid high-risk orbital regions and optimize spacecraft trajectories.

ACTIVE DEBRIS REMOVAL

While detection systems may prove key for avoiding smaller fragments of debris, active removal technologies are being developed to address larger debris objects. These systems employ robotic capture mechanisms combined with autonomous guidance and control systems to approach, capture, and deorbit defunct satellites and rocket stages.

Switzerland-based ClearSpace is the world’s leading company developing active debris removal spacecraft.

The technology it is developing will be platform agnostic, with slight variations according to the mission and spacecraft. Importantly, core systems such as the guidance, navigation and control (GNC) will be similar.

The robotic capture systems employ multiple articulated arms designed to secure large debris objects safely. The systems are designed to operate autonomously while engineers on the ground provide oversight at critical decision points.

Comprehensive ground testing programs are essential for validating debris removal technologies before their operational deployment. Testing challenges include simulating zero-gravity conditions, validating autonomous operation sequences, and demonstrating reliable capture mechanisms for uncooperative targets.

Engineers are ground testing the robotics in laboratories using low-friction surfaces with precision ball bearings to simulate the zero-gravity conditions. The tests enable the validation of capture sequences and control algorithms before flight deployment.

Closed-loop testing validates the GNC systems by combining sensor inputs with flight software and control outputs. This enables system validation while maintaining the safety and cost benefits of ground-based testing.

The testing programs are also addressing the challenges of operating in the space environment, including thermal cycling, radiation effects, and long-term reliability requirements. Component selection emphasizes solid-state systems that can survive launch environments and operate reliably for extended periods.

Vision and radar systems provide the precision guidance necessary for proximity operations around uncooperative targets. Dark room testing facilities are being used to simulate the space environment, with robotic systems that recreate relative motion between the servicer spacecraft and target while validating sensor performance and control algorithms. The dark rooms can even simulate sun angles and eclipse conditions to cover the entire gamut of lighting conditions that may be encountered during space operations.

Nicolas Croisard, system architect at ClearSpace says, “We mount the sensors that will ultimately be on our servicer onto a robot, and a mock-up of the client object on another robot. Then we simulate the relative trajectory using these robots, and use what our sensors perceive as input to our control algorithm. “You have a completely dark room, and a sun simulator – a big flashlight that points in whatever direction you want it to, and the robots move together.”

INTEGRATION AND COMMERCIAL VIABILITY

The space sector may be able to deal with different debris size categories appropriately by combining technologies such as passive monitoring with active intervention capabilities. Small debris detection would provide the environmental awareness necessary for collision avoidance and mission planning, while active removal systems would address the large objects that pose a critical collision risk.

Active removal missions would be planned and executed based on collision risk assessments and orbital mechanics constraints. A modular approach to robotic systems would enable different mission configurations optimized for specific debris types and orbital regimes.

“Tackling space debris isn’t a one-size-fits-all challenge. You will need a fleet of specialized servicing spacecraft – most likely a spacecraft would be limited to a subset of activities,” Croisard says.

“The vehicles themselves will have limited operational lifetimes, so we design with lifecycle efficiency and mission modularity in mind, ensuring long-term sustainability and cost-effectiveness.”

The economic viability of debris removal operations is also a key consideration for ClearSpace. Debris removal missions need to be regular and routine, not large one-off government-funded Moon shots.

The program is targeting cost levels that enable sustainable commercial operations – single-digit or low double-digit million-dollar mission costs. Croisard is cognizant that cost-effective, scalable technologies are required.

Automation is central to the service model. The use of automated systems will reduce operational costs by minimizing ground control requirements while maintaining safety through supervised autonomy.

“Cost efficiency isn’t just desirable – it’s essential to scaling debris removal as a viable commercial service,” Croisard says. A modular approach to system design enables production economies of scale while allowing mission-specific customization. Common subsystems include guidance and control systems, robotic mechanisms, and sensor suites. These could be manufactured in larger quantities and adapted for different mission requirements. “A lot of the software and the way that operations will be performed will be similar. A lot of the sensors will be very similar,” Croisard says.

MULTI-DOMAIN APPLICATIONS

Space debris removal requires significant advances in operational efficiency compared to traditional space missions, while maintaining the reliability necessary for proximity operations around valuable space assets.

Fortunately, the technical capabilities developed for space debris applications extend to other challenging space operations, including satellite servicing, life extension missions, and lunar landing systems. This broader applicability helps justify development investments and provides multiple revenue streams for commercial operators.

Millimeter-wave radar systems demonstrate utility for lunar landing applications, where dust and lighting conditions challenge optical systems. “One of the great benefits of millimeter-wave radar is that it will see through dust,” Jacklin says. “When you are within proximity of the lunar surface, you are kicking up a lot of dust, which is going to interfere with any kind of laser guidance or laser ranging type systems.”

The robotic systems developed for debris capture – autonomous rendezvous, capture, and stabilization – can be adapted for satellite servicing missions, including refueling, component replacement and life extension services. Such applications provide more commercial opportunities and advance the core technologies needed for debris removal.

“There are life extension missions if the asset is still operating normally, but it’s just reaching its end of life, usually because of a lack of propellant,” Croisard says. “Here, our spacecraft could take over the station-keeping duty, which requires propellant.”

The guidance and control systems developed for proximity operations around uncooperative debris objects also provide the building blocks for more complex operations. These could include orbital assembly and construction missions that support future space infrastructure development.

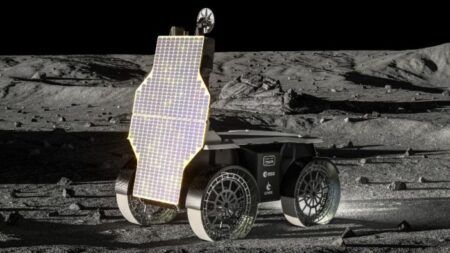

ClearSpace’s operational demonstrations are planned for within the current decade, with several missions planned to validate different aspects of debris monitoring and removal technologies. These missions will provide the operational experience necessary to transition from demonstration to routine operations and validate core technologies. The first mission, ClearSpace-1, is planned to launch towards the end of next year and will be the first large-scale active debris removal demonstration.

ClearSpace-1 will capture and deorbit the defunct ESA satellite Proba 1, with both destroyed upon atmospheric re-entry. The initial target was VESPA, but the defunct rocket part was hit by debris and its course altered last year. The mission will validate the complete operational sequence of an active debris removal.

Plextek is developing the millimeter wave radar that ClearSpace is using for its spacecraft.

“We developed a debris-detecting radar in nine months. We were able to quickly design and build it thanks to our experience in millimeter wave radars gained in other areas,” Jacklin says.

Subsequent missions will focus on debris detection and characterization, deploying millimeter-wave radar systems to gather the environmental data necessary for comprehensive debris modeling. These missions will provide the situational awareness foundation for both collision avoidance and active removal operations.

The timeline for full operational capability extends through the current decade. Commercial operations are expected to begin as regulatory frameworks develop and market demand increases for debris removal services.

The technical solutions to the problem of space debris are a confluence of advanced radar, autonomous robotics, and commercial space’s operational capabilities. While the orbital space debris problem continues to grow, the technical foundations for solving it are being laid through partnerships and innovative testing now.

Success in implementing the technologies will determine whether Earth’s orbit remains accessible for future generations or becomes a dustbin in the sky.

THE UNSEEN NATURE AND THREAT OF SPACE DEBRIS

Massimiliano Vasile, professor of space systems engineering and director of the Aerospace Centre of Excellence at the University of Strathclyde is an expert is space debris. The University of Strathclyde recently started a £1.5 million (US$2 million) project with the UK Space Agency about space traffic management and debris forecasting.

“We have a good knowledge of objects above 10cm. We don’t have good knowledge about what they are. We have far less knowledge about small fragments,” he says.

“There are sensors, radar, laser and cameras that can be used in Low Earth Orbit, and different ones that can be used in geostationary orbit. “There are also sensors of limited usefulness on the ground. Modeling and simulation that predicts the evolution of the space environment can tell you what will happen when you launch a new satellite. This is also essential for developing space policy,” he says.

However, even if you have a model, engineers still need to know what the debris is. Space traffic management also needs accurate modeling so it can predict if there is risk of a collision with debris.

“The solution is to put sensors into space, capable of tracking and measuring objects, including debris. But we don’t yet have the range of sensors needed, and we also need to find a way to share all the data,” Vasile says. “The problem is getting worse. Most people don’t understand its magnitude,” he adds.

“There is a growing tension between the problem and the launching of more satellites. It’s not a matter of ‘if’, it’s a matter of ‘when’ there is a disruptive incident.

“We are already above the limits of a cascade event and the amount of collision avoidance maneuvers is growing. The problem is being felt by the operators, who see the economic damage, but it doesn’t make headlines.

“So there are many different things that need to be done. We need to avoid collision from traffic and exploding objects. We need to remove what is there already and avoid making more junk. But it will get worse, a point when it starts severely hitting pockets and causes disruption.”