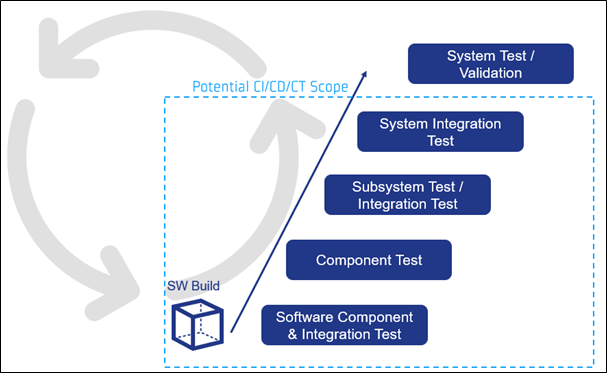

Ground test rigs remain central to aerospace development, but the way we use them can evolve. Traditionally, higher-level integration testing on the right side of the V-model happens late in the process and mainly on larger HiLs or iron birds.

By interconnecting component-level HiLs and dynamically combining them into subsystem and system configurations, integration can begin earlier in the cycle. This approach helps detect issues sooner, reduce iteration time, and make existing test resources more efficient.

From isolated HiLs to a software-defined test environment

Usually component HiLs are compact, automatable, and increasingly remote accessible. When designed to communicate through software-configurable bus systems such as CAN, LIN, or avionics interfaces, these units can be flexibly combined into larger test setups.

Using a software-defined connection layer, several component HiLs can form a subsystem test environment, or even a system-level configuration, without additional dedicated hardware.

At Schleissheimer, this concept is being explored through a series of internal and customer-oriented concept studies. Based on a fleet of remotely accessible Micro HiLs, the research focuses on how dynamically networked test setups can reproduce system-level interactions and enable earlier integration testing.

Earlier feedback and higher ROI

The most immediate benefit of this approach is earlier and broader feedback. Networked HiLs make it possible to reveal timing conflicts, bus load problems, and interface mismatches long before the iron bird stage. By testing integration logic earlier, teams can reduce rework during final integration and shorten development loops.

In addition, the modular nature of these setups supports efficient reuse. If two aircraft programmes share a large percentage of common ECUs, a dynamic reconfiguration allows the same component HiLs to be used for both platforms with minimal adaptation. This not only increases the return on investment of existing rigs, but also supports a sustainable, platform-spanning test infrastructure.

Complementing, Not Replacing, the Iron Bird

This shift-left strategy is not intended to replace iron-bird testing. Full-scale rigs remain essential for validating the complete aircraft system with hydraulics, full channel counts, and mechanical loads.

However, by finding issues earlier that would otherwise appear later, networked component HiLs make iron-bird campaigns more efficient and focused. In this way, they strengthen rather than substitute the traditional high-integration test phase.

Outlook

By combining flexible test architectures with remote accessibility and intelligent orchestration, the aerospace industry can gain a more connected and adaptive ground test landscape. The result is a higher level of integration maturity earlier in the process, a decisive advantage in the race for faster, and more cost-efficient aircraft development.