Swiss electric propulsion company H55 has completed the first regulator-approved propulsion battery module certification test sequence, hailing the milestone as removing a critical barrier that constrains the commercialization and financing of electric aircraft.

The six-month test campaign was supervised by the European Union Aviation Safety Agency (EASA) and was completed last December.

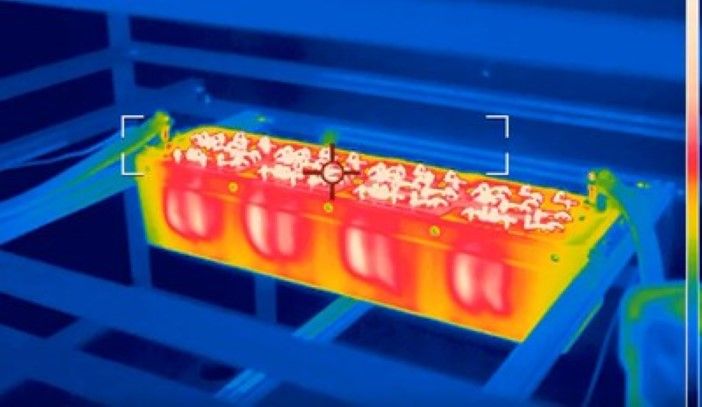

During testing, H55’s battery pack was subjected to various environmental, safety, functional, and performance conditions under worst-case failure modes, including authority-witnessed thermal runaway tests without propagation – explosions.

Serial production of aircraft propulsion batteries

H55 produced more than 100 test articles drawn from its approved and audited product configuration for the testing. The hardware was serial-conforming rather than prototype-based, manufactured through validated processes on regulatory-approved production lines.

The campaign provides certification-level evidence that commercial lithium battery cells can be integrated into aviation propulsion battery systems capable of safely containing worst-case failure scenarios.

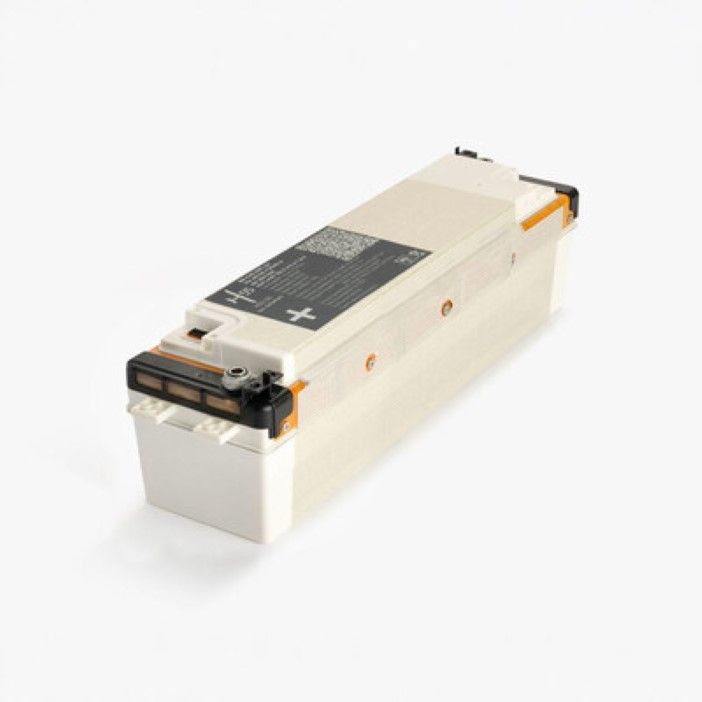

H55’s patented Energy Storage System (ESS) embeds monitoring, redundancy, and hazard mitigation at the cell level, ensuring containment of extreme failure conditions consistent with aviation safety requirements.

According to H55, it is the only organization holding both EASA Design Organisation Approval (DOA) and Production Organisation Approval (POA) for electric propulsion systems.

H55’s batteries will power larger aircraft expected to fly this year

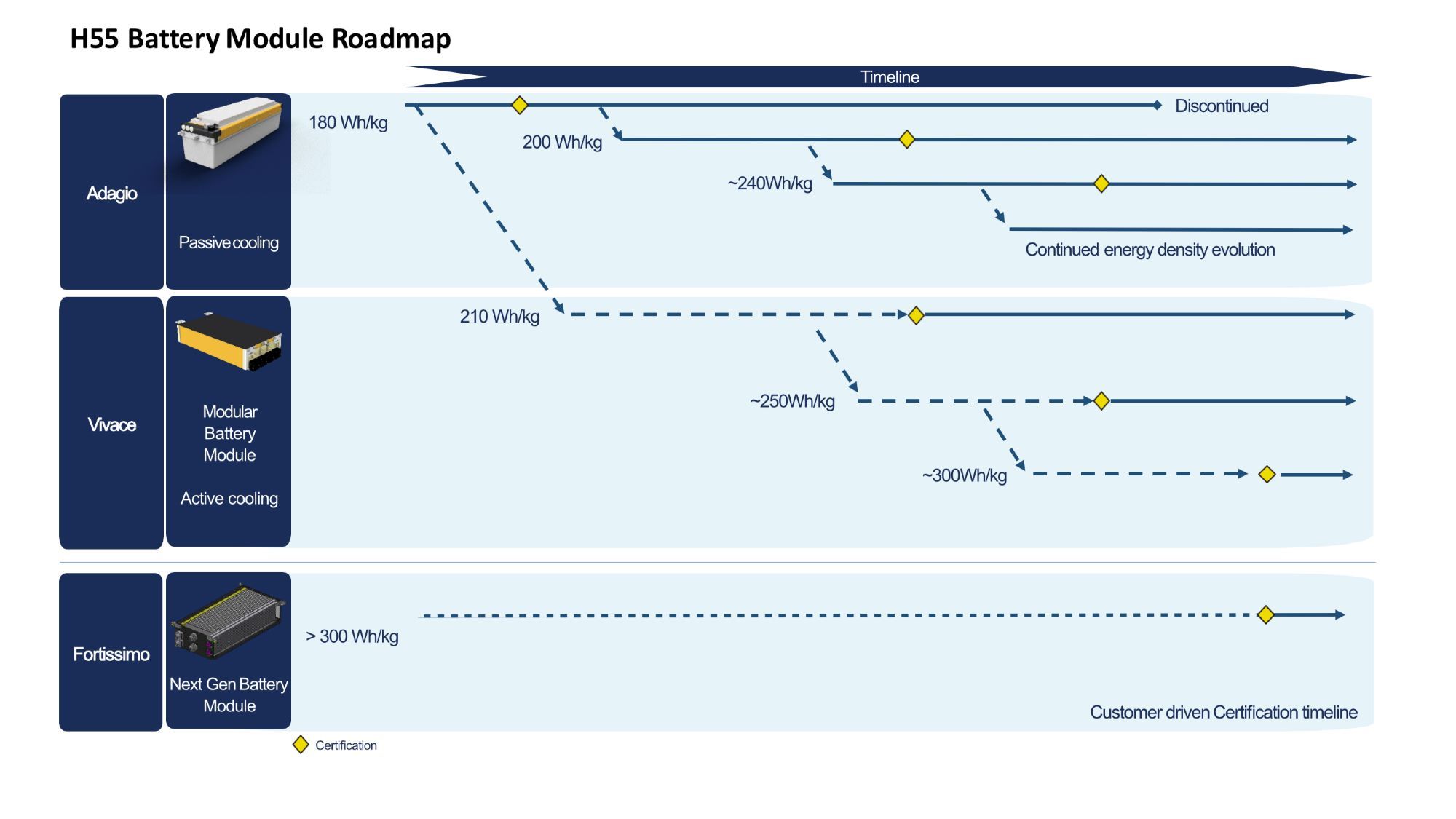

While electric aircraft that use Lithium-ion batteries for propulsion such as the two-seater Pipistrel Velis Electro are already on the market, they are certified specifically in the CS-LSA (Light Sport Aircraft) category. The Velis Electro uses two liquid-cooled, 11 kWh lithium-ion battery packs, relatively small compared to H55’s battery packs, the first version of which will have a capacity of 104 kWh.

Additionally H55’s lithium battery-containing ESS is being certified to CS23 (Certification Standard), which covers larger aircraft – at different levels – of up to 19 seats including commuter and utility aircraft.

H55 expects to receive EASA certification for its ESS in the coming months and for the first aircraft using the system to fly this year. the BRM B23 Energic, CAE’s all-electric pilot training aircraft, and the hybrid-electric Dash 8 demonstration programme with Pratt & Whitney Canada.

The H55 batteries will achieve US certification by way of a mutual recognition arrangement the Federal Aviation Administration (FAA) has with EASA for ongoing programs. Test results will be shared with the FAA, providing a basis for supporting and accelerating H55’s US certification activities.

Cell-level monitoring that enables asset transparency

André Borschberg, executive chairman and co-founder of H55, said, “Electric aviation can be engineered to meet the same certification discipline and safety expectations as conventional aircraft.”

Rob Solomon, CEO of H55, said, “By completing the first EASA-agreed battery module test campaign, H55 has addressed the most critical technical bottleneck on the certification path.

The cell-level monitoring H55’s batteries feature is important because it enables transparent asset data for regulatory type certification and fleet insurability, added Solomon.

Sébastien Aymon-Demont, co-founder and chief technology officer of H55, said, “By designing protection, monitoring, and mitigation directly at cell level, rather than relying on pack-level assumptions, we have built a fundamentally different ESS.

“This cell-level architecture not only enables effective protection at the point of origin, but also allows us to optimise battery efficiency, performance, and long-term reliability — all of which are essential for certifiable electric aviation.”

H55, based in Sion, Switzerland, was founded as the technological legacy of the Solar Impulse program. The company has accumulated more than 2,000 hours of fully electric flight with zero battery-related incidents across six electric aircraft it has designed, built, and flown.