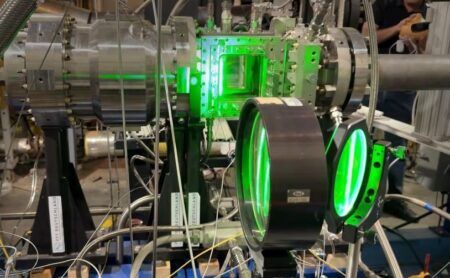

Beehive Industries has completed high-altitude testing of its additively manufactured Frenzy turbojet engine, validating its ignition capability and performance across the full flight envelope at a government test facility in Ohio, USA.

The 200 lbf thrust engine underwent vacuum chamber testing, which confirmed successful ignition and operation at altitude, rapid acceleration from light-off to maximum speed, and turbine temperatures and thrust-specific fuel consumption that were better than predicted.

Hardware condition after mission-life equivalent runtime was described as “like new” by the Denver-based company.

Beehive shipped two prototype engines to the US Air Force (USAF) facility in October following ground testing of six engines in four months. The altitude campaign results met or exceeded Air Force requirements, according to the company.

David Kimball, chief technology officer at Beehive Industries, said, “In less than a year, we’ve gone from concept to proven high-altitude performance, and we’re doing it ahead of schedule because of the talented and determined team at Beehive. Frenzy is now flight-ready, and our production system is ready to scale alongside it.”

The Frenzy engine family spans 100-300 lbf and is designed to power next-generation uncrewed aerial systems. Development is supported by a US$12.46 million contract from the USAF Rapid Sustainment Office (RSO) and the University of Dayton Research Institute (UDRI), awarded in October 2024.

Beehive’s additive-first manufacturing approach compresses traditional aerospace development cycles from years to months, the company said. The technique enables production of complex engine geometries that would be difficult or impossible to achieve through conventional manufacturing methods.

Flight testing is planned for early 2026, with integration into the first flight vehicle representing the final step before low-rate initial production. Beehive’s facilities in Denver, Cincinnati and Knoxville are ramping capacity to meet anticipated demand.

“This test campaign not only demonstrates the full potential of our engine, but also how we move with speed through a highly iterative, cross-functional development program,” Kimball added. “Each milestone strengthens our confidence in the architecture and our ability to deliver on our commitments.”