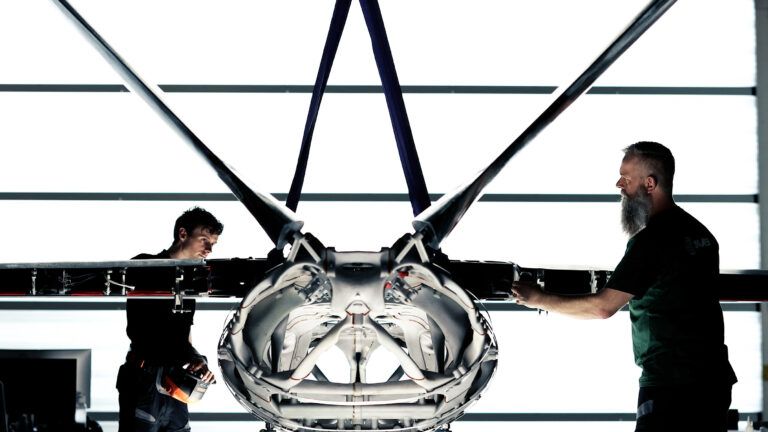

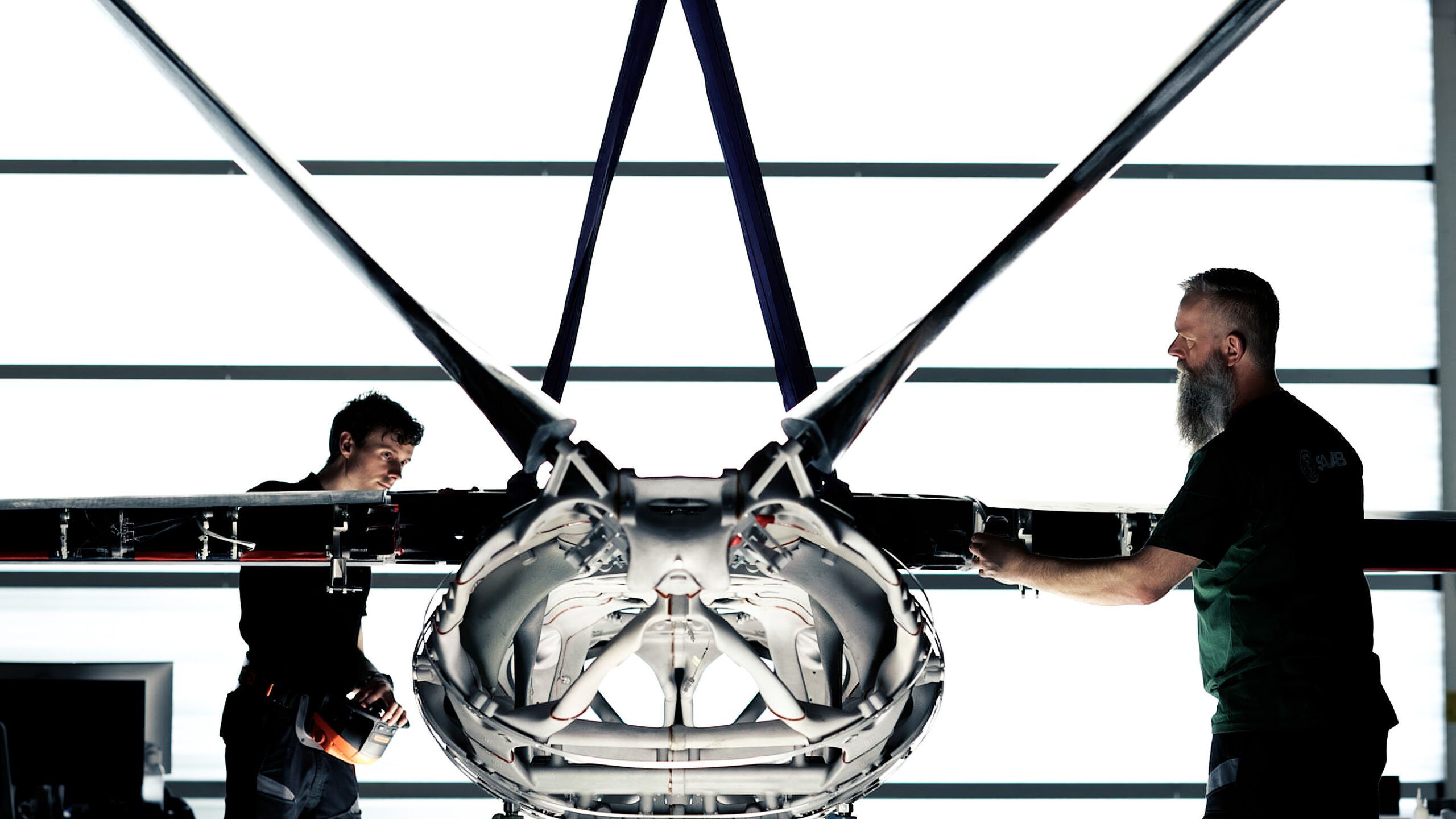

Saab and 3D printing company Divergent have used additive manufacturing to produce one of the largest fuselages ever for powered flight.

Designed and manufactured in partnership by the two companies, the fuselage is 15ft (4.5m) long and comprises 26 printed parts, each joined and bonded by robots.

The fuselage has been delivered to Saab for vehicle integration and flight testing for an autonomous aircraft project. It will be amongst the largest ever laser powder bed fusion structures to undergo powered flight when tested.

Los Angeles, California-based Divergent was founded in 2014 and supplies parts and structures to the automotive and aerospace sectors. The company has developed a fully software-defined end-to-end system that uses a powder bed fusion additive manufacturing process and no unique tooling or fixturing.

Axel Bååthe, head of Rainforest, Saab’s internal innovation department, said, “Adopting Divergent’s additively manufactured and digitally designed structures in this effort has given our joint team unparalleled flexibility in this development process. We see digital design and advanced manufacturing as a key enabler of our collaborative success in this project.”

Divergent Adaptive Production System (DAPS) is an end-to-end structural engineering design and manufacturing system leveraging AI-driven design, industrial-rate additive manufacturing, and universal robotic assembly to deliver structures that are faster to develop, higher performance, and lower cost than their conventionally designed and manufactured alternatives.

Lukas Czinger, co-founder and CEO of Divergent said, “This collaboration with Saab highlights what becomes possible when ambitious aircraft concepts are paired with an end-to-end, software-defined manufacturing platform. By tightly integrating digital design, additive manufacturing, and automated assembly, our teams were able to realize a large-scale fuselage structure aligned with Saab’s vision, while moving with a level of speed, flexibility, and structural integration that traditional approaches cannot match.”