MIT engineers have developed a technique called nanostitching that uses carbon nanotubes to prevent cracking in multilayered composite materials which could be used to make lighter and tougher airplabes and spacecraft.

Engineers are using advanced composites made from high-performance fibers embedded in polymer sheet to build lightweight, durable aircraft structures. However, composites have a vulnerability – the space between layers filled with polymer ‘glue’. Upon impact, cracks can easily spread between layers, weakening the material even without visible exterior damage.

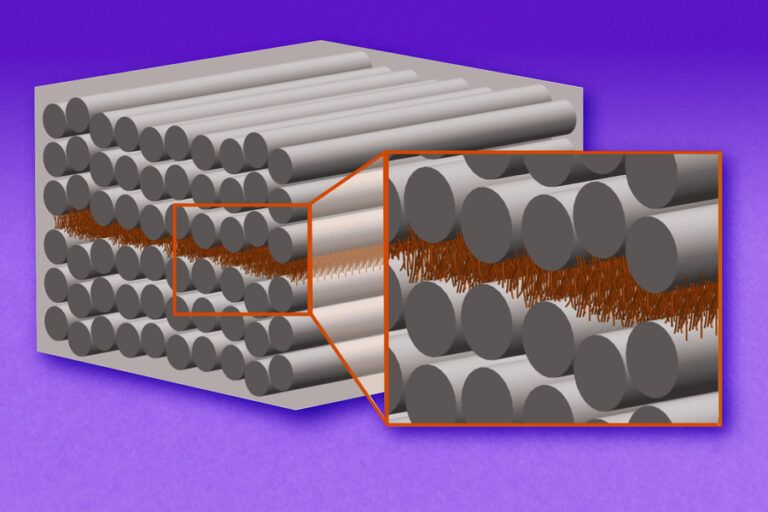

A team of researchers at MIT has demonstrated nanostitching, where microscopic forests of chemically grown carbon nanotubes are deposited between composite layers. The tiny, densely packed fibers grip and hold the layers together like ultrastrong Velcro, preventing them from peeling or shearing apart.

In recent tests with an advanced thin-ply carbon fiber laminate composite, layers bonded with nanostitching improved the material’s resistance to cracks by up to 60% compared to those with conventional polymers.

Professor of aeronautics and astronautics at MIT Brian Wardle said, “The interlaminar region is the Achilles’ heel of composites. We’re showing that nanostitching makes this normally weak region so strong and tough that a crack will not grow there.

“We could expect the next generation of aircraft to have composites held together with this nano-Velcro, to make aircraft safer and have greater longevity.”

The researchers tested the nanostitched composites’ resistance to the three main delamination modes where cracks can spread between layers, causing peeling, sliding, or a combination of both.

“This is a new composite technology, turbocharged by our nanotubes,” Wardle said.

Stephen Tsai, emeritus professor of aeronautics and astronautics at Stanford University said, “The authors have demonstrated that thin plies and nanostitching together have made significant increase in toughness. Composites are degraded by their weak interlaminar strength. Any improvement shown in this work will increase the design allowable, and reduce the weight and cost of composites technology.”

The researchers envision nanostitching could make any vehicle or structure using conventional composites lighter, tougher and more resilient. “You could have selective reinforcement of problematic areas, to reinforce holes or bolted joints, or places where delamination might happen,” said Carolina Furtado, a researcher on the project and professor at the University of Porto, Portugal. “This opens a big window of opportunity.”

This article edited for style and length from the original written by Jennifer Chu and published at MIT news