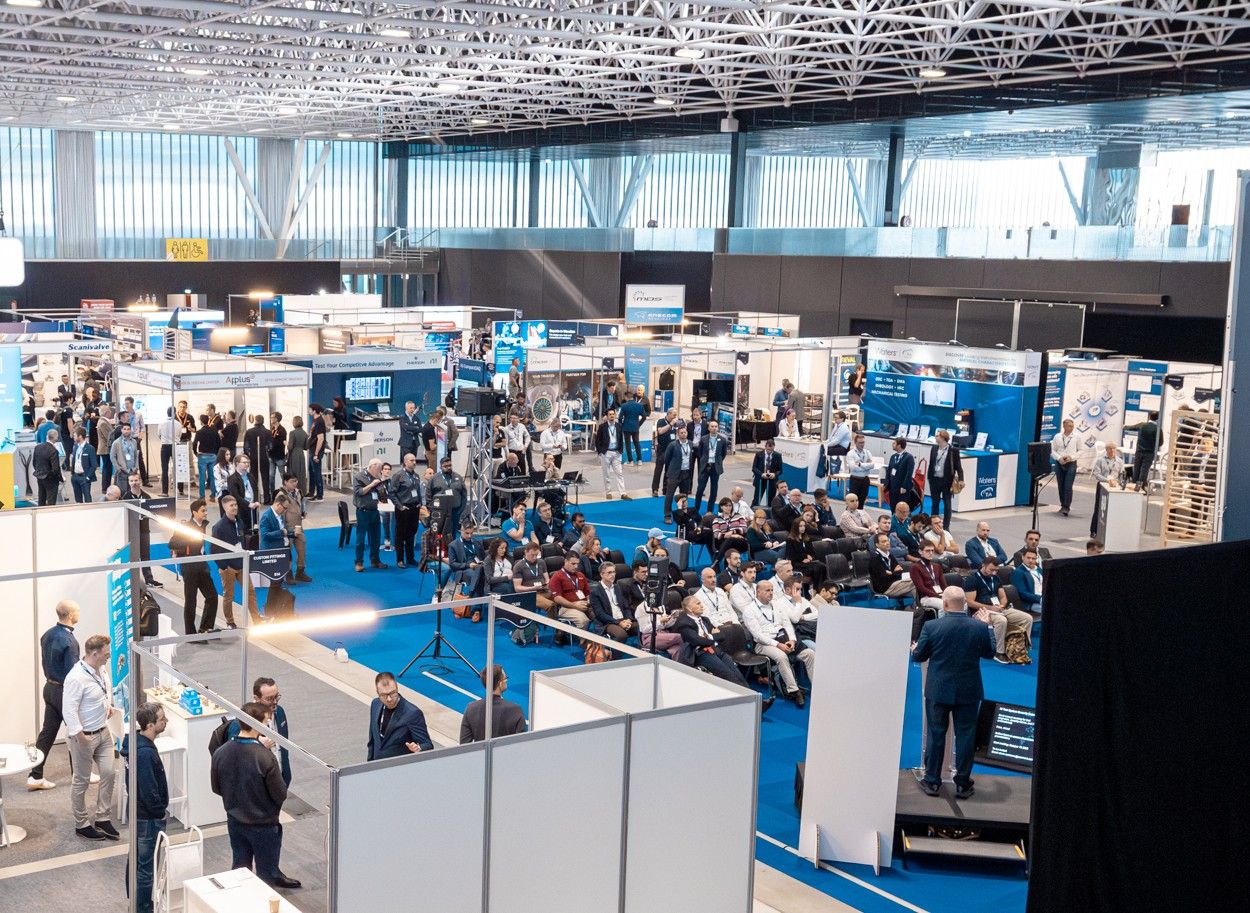

Industry leaders gathered to showcase innovations spanning hybrid electric propulsion, AI-powered data analytics, digital certification pathways and advanced sensor technologies during the Open Testing Forum at Aerospace Test & Development Show 2025. The two-day event demonstrated how modern testing approaches are accelerating aircraft development, while reducing costs and improving safety validation and featured 140 companies exhibiting their latest testing technologies and solutions.

Hybrid-electric propulsion bridges present and future

John Rees, UK chief engineer at Ampaire, presented the company’s approach to hybrid electric aircraft development. Ampaire is developing several hybrid architectures including series, parallel and integrated configurations, each optimized for specific mission profiles and aircraft types.

The company has accumulated flight test experience across various platforms, including extended operations in Hawaii, cross-country flights in the USA and cold weather testing in Alaska. A 12-hour endurance flight covering nearly 1,400 miles (2,253km) demonstrated the technology’s viability for regional operations.

“The dream is valid, but it must be executable,” Rees said. “Electrification is a journey, not only whether you’re building, flying or investing.”

Ampaire’s Eco Caravan retrofit, based on the Cessna Caravan, achieves 50% to 70% fuel savings depending on route profile, translating to 25% to 40% reduction in direct operating costs. The integrated parallel architecture mechanically couples electric and combustion propulsion systems, enabling optimized power distribution across different flight phases.

Also during day one, Mattia Padulo, chief technical officer and chief engineer for regional aircraft at Aura Aero, discussed his company’s progression from the Integral two-seater trainer to the ambitious 19-seat hybrid-electric ERA program. The ERA features eight electric engines mounted on the wings, with power generation achieved through turbogenerators and battery packs working at optimal points depending on mission requirements.

“This kind of small aircraft are an excellent stepping stone toward aircraft in the CS 25 category,” Padulo said. “They will involve new standards and public exposure, and this kind of feeling from the public would be very useful feedback toward deciding on larger aircraft.”

Hydrogen engine advances toward flight

Dr Adam Harris, global chief of test facilities at Rolls-Royce, detailed Project Cavendish, the aeroengine maker’s main project developing and testing hydrogen propulsion technology, which is using a Pearl 15 engine modified to run on gaseous and eventually liquid hydrogen.

The project has two phases: Engine Zero testing in Dahlewitz, Germany, which validated thermal management and hydro-mechanical actuation systems using kerosene and liquid nitrogen as a hydrogen simulant, and the current phase preparing for gaseous hydrogen testing at NASA Stennis in Mississippi, USA.

A critical component involved building a full-scale fuel system emulation at the Health and Safety Executive laboratory in Buxton, UK. This allowed the team to validate fuel system performance and correlate physical testing with Simcenter multi-physics modeling before integrating with the actual engine.

Digital certification pathways for modular aircraft

Tim Williams, chief engineer at Aeralis, and Anton Burford, director of capability at Aeralis, presented their approach to developing a modular jet trainer through extensive digital engineering and novel certification strategies.

The Aeralis concept centers on a common core fuselage adaptable to multiple configurations through interchangeable wings, empennage and cockpit arrangements. The digital enterprise approach encompasses manufacturing, design, certification, configuration control and operational support.

“We’re not going to do everything digitally,” Burford said. “What we’re doing is balancing the digital space with the physical space, recognizing where modeling is accurate enough for direct evidence and where physical testing remains necessary.”

A recent project by the company demonstrated the workflow by developing an emergency power generation system entirely from functional models, which suppliers used to create physical test rigs. The team successfully demonstrated digital thread traceability and created a regulator portal delivering evidence directly to certification authorities in their preferred format.

and Anton Burford, Director Capability from Aeralis on stage at the Aerospace Test & Development Conference 2025 (Image: Mark Allen Group)

A321XLR certification campaign

Jim Fawcett, lead flight test engineer at Airbus, provided insights into the extensive flight test campaign for the A321XLR, which accumulated 1,500 flight-test hours across nearly 450 flights using three test aircraft before achieving EASA certification in July 2024.

Despite external similarities to previous A321 variants, significant internal changes drove extensive testing requirements. The aircraft features an increased maximum takeoff weight of 101 tons (92 tonnes), a new Rear Center Tank adding substantial extra fuel capacity, and modified landing gear and braking systems.

“We had to extend the belly fairing on the rear fuselage following some changes in rule making by the FAA, who required us to boost the crash worthiness of the aircraft,” Fawcett said during his day two presentation.

The flight test program included a 13-hour endurance flight to validate fuel system operation at cold temperatures, during which Fawcett’s team traced a 500km-wide “XLR” logo in the sky over Europe. Crosswind testing in Iceland demonstrated a 38-knot crosswind capability.

Ariane 6 test campaign

Arnaud Demay, Ariane 6 qualification project manager at Ariane Group, provided an overview of the intensive system test campaigns conducted in the 12 months before the European space launch system’s inaugural flight on July 9, 2024.

“We had so many system tests, including full cryogenic tests with the engine, which we did in parallel with hot fire tests in Germany with the upper stage Vinci engine and the new auxiliary propulsion unit. We did a lot of tests with cryogenic arm for launch and full avionic and flight software qualification,” Demay explained while on stage.

“In those 12 months we have to be absolutely sure of everything on our own, because there is no official qualification in Europe, there is no equivalent to the FAA.”

One of the most challenging aspects involved the cryogenic arms that connect the launcher to ground systems and supply and manage the rocket’s liquid hydrogen and oxygen fuel. “At the moment of lift-off, in less than 2.6 seconds, those cryogenic arms disconnect and pivot away to release the launcher,” Demay said.

Managing test in large facilities

A panel discussion on test facility management featured Brad Becktell from GE Aerospace, Pete Smith from Airbus, Chad Killeen from Bell Flight and Luigi Foschini from EN4, moderated by Nick Butler from NI Emerson.

Panelists emphasized treating test facilities as competitive internal service providers rather than merely compliance operations. Technology trends discussed included hybrid testing, combining physical and virtual approaches, single data platforms that unify engineering tools and phenomena-based testing replacing traditional strength validation.

Luigi Foschini, Technical Director, EN4

Chad Killeen, Director Mechanical Test Labs, Bell, Pete Smith, Head of Structures Test, Airbus (Image: Mark Allen Group)

“Tomorrow’s world is that we’re measuring different things for different purposes,” Smith said. “We want to compare that data with lots of different sources – it’s a little different than someone coming along and saying test my structure for 500,000 cycles.”

Chad Killeen discussed Bell’s approach to facility management: “I treat my operation as almost a company within a company. We have our own mission, our own values, focused on four key principles – safety for both people and test articles, getting to question answers quickly, quality that certification authorities can trust and innovation in every aspect of our operation.”

Physical testing’s future in certification

Pete Smith, head of structures test at Airbus, challenged the aerospace community to consider if physical testing will remain central to aircraft certification given increasing maturity of virtual testing methods.

“Today, our airworthiness authorities set requirements, this is the ruling dimension for us,” Smith said. “If you have a new structure, new materials, new architectures, you have to do a physical test.”

To many, the future lies in demonstrating that physical testing equals virtual testing. Engineers use a credibility assurance framework to demonstrate this equivalence, following an integrated workflow where extensive virtual testing de-risks design before building anything.

However, Smith emphasized that truly novel requirements will always require physical testing initially, citing examples including hydrogen fuel systems, external rotor engines and folding wingtips. He issued a direct call to the testing community: “Please help us to improve. Find new and novel solutions to shift data, measure data, store data and compare data.”

AI transforms test data analysis

Speaking on day one Thomas Ricou, AI technical leader at France-based Spherea, outlined how AI technologies are addressing persistent challenges in aerospace testing, including reducing development cycles, managing legacy data and preserving critical knowledge amid workforce turnover.

The company has developed AI tools for three key areas: structuring historical test reports, accelerating test program development and enhancing technical documentation searchability. One system automatically extracts test results and architecture from thousands of legacy test reports with 100% accuracy, enabling trend analysis and predictive maintenance capabilities.

“The future is built on expert AI collaboration,” Ricou said. “AI will not replace experts, but it will become a very powerful tool for us.”

Cybersecurity regulations to reshape test engineering

Steve Summers, offering manager and security lead at Emerson NI’s Test & Measurement Business Group, delivered insights about the European Cyber Resilience Act (CRA) and its implications for test system development and procurement.

The CRA, which takes full effect in December 2027, will require that all products sold in Europe bear a new CE mark demonstrating compliance with cybersecurity controls. Products must ship with no known vulnerabilities and include a complete software bill of materials with five years of support guaranteed.

“Cybersecurity will drive the largest investment in test and measurement of our careers,” Summers said. “The job of test engineers is about to change.”

20 years of UAS testing lessons

Wing Commander Keirin Joyce from the Royal Australian Air Force delivered a comprehensive retrospective on two decades of uncrewed aerial systems (UAS) testing and acquisition.

Joyce outlined four key principles that have driven successful UAS programs: “Number one, know your requirements, stick to them and test them very thoroughly. Number two, use dedicated and expert operators and testers. Number three, narrow the scope of your project pragmatically when applicable and required. And number four, be flexible and decentralized as you execute your program.”

The presentation highlighted how the Australian Defence Force has successfully leveraged partnerships and existing operational test evaluation reports from allies to accelerate programs. Joyce also discussed the value of innovation programs in staying at the leading edge of UAS technology.

Virtual testing for aerospace structures

Bram Noordman, R&D engineer at the Royal Netherlands Aerospace Centre (NLR), demonstrated how virtual testing methods can complement and enhance physical testing programs. His work, conducted as part of the Clean Sky 2 MANTA (MovAbles for Next generaTion Aircraft) project, used a building block approach that progressively increased complexity from simple cantilever beams to realistic aerospace structures like morphing wing flaps.

“If you have a high fidelity finite element model, I can make a reduced order model of it that works much faster than a high fidelity model, which can take hours to simulate,” Noordman explained while on stage.

The virtual testing approach proved valuable for both predicting test outcomes and identifying potential issues before physical testing. The reduced order models demonstrated good accuracy in predicting forces, displacements and oil flow in servo-hydraulic actuator systems, with simulation times reduced from hours to seconds for complex structures.

The emerging theme over the two days was that aerospace testing is undergoing fundamental transformation, with digital approaches, alternative propulsion systems and advanced analytics reshaping how the industry validates new technologies while maintaining rigorous safety standards.

This is just a selection of the presentations from the Open Testing Forum. Running at the same time was the Future Propulsion Forum conference area, and an exhibition with 140 companies demonstrating the latest testing technologies and services – all free to attend for industry professionals.

Check the event website https://aerotestdevelopmentshow.com/ for more details on 2025’s presentations and how to get involved with the 2026 event in the coming weeks!