Researchers in Germany have successfully tested a flexible skin for wings which reduces aircraft noise.

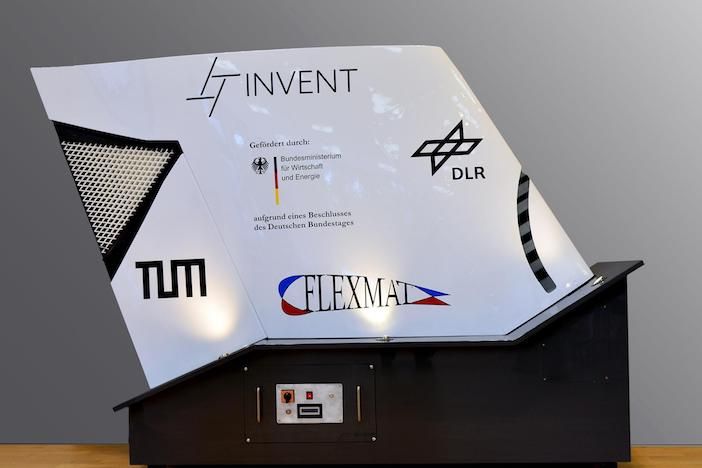

The artificial skin, which is made of synthetic rubber and glass-fibre reinforced composites was tested on a demonstration model by the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR), Invent GmbH and the Technical University of Munich as part of the FlexMat project.

Some of the noise from an aircraft’s wing is generated where high-lift devices and control surfaces meet the wing and there is an abrupt transition between these aerofoils and the air flowing around them to the fixed part of the wing.

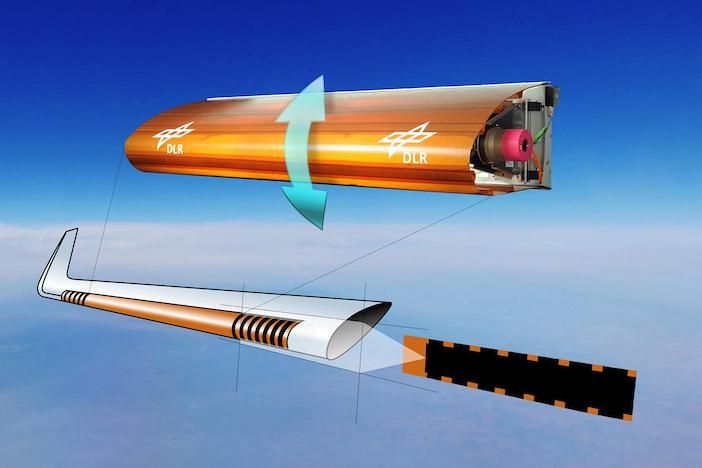

For the study, engineers developed a wing where direct transitions between the fixed part of the wing and the moving control surfaces or high-lift devices were avoided. Instead they were achieved with a flexible skin between the fixed wing and the moving components.

The skin had to be able to withstand extreme aerodynamic loads, but must not be too stiff, otherwise the systems driving the moving components would have to be able to exert additional force.

Martin Radestock of the DLR Institute of Composite Structures and Adaptive Systems in Braunschweig said, “Continuous transitions between flap systems and the main aerofoil would be a huge advantage for future laminar flow wings, which allow air to pass around them without turbulence. This could reduce airflow turbulence and ensure laminar stability.”

Laminar flow wings result in lower drag, which is beneficial for the environment.

An aircraft configuration based on the Airbus A320 provided the foundation for research on FlexMat.

“We concentrated on the outboard area of the wing,” said Radestock. “The slat on the leading edge was replaced with a variable-shape leading edge, referred to as a droop flap, which was developed and researched at our institute back in 2007. We also installed our transition skin.” A transition triangle from the Technical University of Munich was applied between the aileron and the trailing edge of the wing.

Materials development

The transition skin tested by DLR has a span of 1m. It consists synthetic rubber – ethylene propylene diene monomer rubber (EPDM) and glass-fibre reinforced composites.

The deformation properties of the transition skin can be adjusted by means of the flexible rubber and the positioning of the rigid glass-fibre strips. The researchers aimed to keep local deformations to a minimum, so that the glass-fibre composites and rubber did not separate.

“The final tests using a demonstrator showed that the wing skin being tested is very hard-wearing and can be deformed to a large extent,” said Radestock. “In the event of extreme deformation, the only thing that needs care is the paintwork, to make sure that it does not crack.”

Testing showed that the use of a flexible skin on wing leading edges is feasible. Further testing will be necessary to check the extent to which noise and drag can be reduced using this technique and the maximum load limit of the skin, DLR said.