The University of Glasgow have commissioned the NextSpace Testrig, the world’s first dedicated facility for testing the structural integrity of materials that will be 3D printed in space.

The NextSpace Testrig addresses critical safety concerns about space manufacturing technologies that could create dangerous debris if not properly tested.

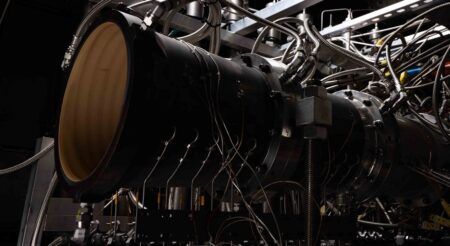

The basement facility at the University of Glasgow’s ames Watt School of Engineering uses a specially-constructed vacuum chamber capable of generating temperatures between -58°F and 482°F (-150°C and +250°C) to create space-like conditions on Earth.

The project was developed by Dr Gilles Bailet in partnership with The Manufacturing Technology Centre, with £253,000 (US$340,000) funding from the UK Space Agency.

Space manufacturing aims to revolutionize how objects are deployed in orbit by using 3D printers to create structures directly in space rather than launching complete devices on rockets. Several experiments have already sent prototype 3D printers into orbit, with astronauts aboard the International Space Station successfully 3D-printing metal parts.

“3D printing is a very promising technology for allowing us to build very complex structures directly in orbit instead of taking them into space on rockets,” said Bailet. “However, the potential also comes with significant risk, which will be magnified if efforts to start 3D printing in space are rushed out instead of being properly tested.”

Objects in space face a hard vacuum that cycles rapidly between extreme temperatures, conditions that can severely affect 3D-printed materials. Imperfections such as tiny bubbles or poorly melted sections that might be negligible on Earth can behave differently in the space environment.

Those flaws could cause printed objects to shatter, scattering dangerous fragments into orbit. These fragments would circle Earth at velocities similar to rifle bullets, potentially causing catastrophic damage to satellites or spacecraft and contributing to the growing space junk problem.

The NextSpace Testrig features a magazine system that can autonomously test multiple samples in a single cycle, making it significantly more efficient than traditional testing methods. The system can apply up to 20 kilonewtons of force, equivalent to 2,000kg, to break samples and analyze their properties in vacuum conditions matching those of space.

The facility can subject samples to cycles of extreme temperatures simulating orbital conditions. It’s designed to test polymers, ceramics and metals that would be printed in space, ensuring they can withstand the physical strains they’ll face in orbit.

Bailet has also patented a prototype 3D printer designed for orbital use, which has been tested during flights on a research aircraft known as the “vomit comet.” The NextSpace Testrig is available to academic colleagues, researchers and commercial clients worldwide.

“We expect that the data we’ll be gathering in the years to come, which can’t be replicated anywhere else in the world at the moment, will help regulatory authorities to make safety standards for in-space manufacturing, informed by real-world testing,” Bailet said.

Iain Hughes, head of the national space innovation program at the UK Space Agency said, “We are proud to have supported the University of Glasgow in developing the world’s first facility for testing 3D-printed materials in space-like conditions. This innovation will help to drive UK advancements in space manufacturing.”