Aerostructures company Spirit AeroSystems is partnering with the Oak Ridge National Laboratory in the USA to develop materials for hypersonic aircraft.

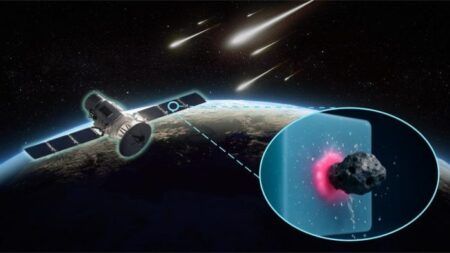

As part of an agreement, Spirit and Oak Ridge’s Manufacturing Demonstration Facility (MDF) will conduct R&D projects on developing scalable and efficient manufacturing processes for advanced materials suitable for use in hypersonic applications in the commercial, defense and space aerostructure markets.

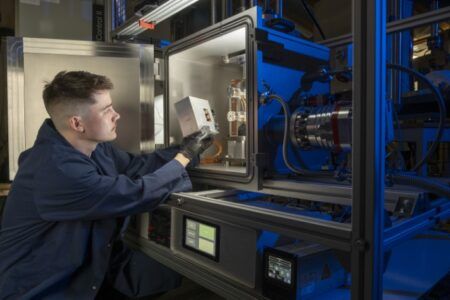

The MDF is managed by the University of Tennessee Battelle and is the largest advanced manufacturing research facility in the USA.

The R&D is to explore advances in high-temperature in-situ process monitoring techniques and predictive modeling capability for microstructure-based performance and certification of carbon and ceramic composites as well as additively manufactured alloys.

In addition, research teams will study various processing techniques for materials that can withstand extreme heat and harsh environments, including the scaling up of a thermal protection system for aerospace platforms.

Technologies are to be developed that range from early MRL 2-4 (manufacturing readiness level), with Spirit bringing its experience of current high-temperature material processing capability at MRL 10.

According to Spirit, the R&D partnership will optimize existing production methods to improve cycle time and rate, and develop alternative process methodologies to enable the efficient and consistent manufacture of derivative and novel advanced ceramic composites and hot structures.

Spirit said, “Testing and qualification are a fundamental part of any process development program yet cost can at times be a deterrent to innovation and improvement. It is the intent of this partnership to address this challenge by incorporating new in situ process monitoring techniques and real time data reduction into the process up front.

“This data will feed artificial intelligence aided process models to dynamically adjust process parameters, ensuring a consistent microstructure is produced. By reducing the manufacturing related scatter in properties throughout the product, accuracy and confidence in predictive modeling techniques allows for a reduced scope physical qualification plan.”

Sean Black, senior vice president, chief technology officer and chief engineer at Spirit AeroSystems said, “With the right manufacturing techniques, machines, and tools capable of reaching a high rate on products, paired with the right approach to manufacture advanced materials and a relentless drive to optimize, means success in designing and modeling fully integrated commercial and defense aerospace systems.”