The design of the parachute for the European Space Agency’s second ExoMars mission is being revised after an unsuccessful high-altitude drop test earlier this month.

The second ExoMars mission, which comprises of the Rosalind Franklin rover and the surface science platform Kazachok, is planned to launch next year .

The rover and surface platform will be encapsulated in a descent module, and transported to Mars by a carrier module, following launch on a Proton rocket from Baikonur, Kazakstan.

The descent module requires two parachutes, each with its own pilot chute for extraction to help slow the craft prior to landing. Following separation of the parachutes, the speed must be suitable for the braking engines to safely deliver the landing platform and the rover onto the surface of Mars. The entire sequence from atmospheric entry to landing takes just six minutes.

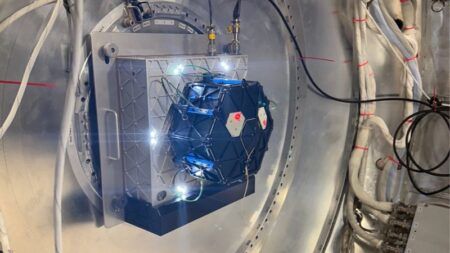

Testing prior to launch has been taking place at the Swedish Space Corporation Esrange site. The first took place last year and demonstrated the successful deployment and inflation of the largest main parachute in a low-altitude drop test from 1.2km, deployed by a helicopter. The parachute has a diameter of 35m, which is the largest parachute ever to fly on a Mars mission.

On May28 this year, the deployment sequence of all four parachutes was tested for the first time from a height of 29km – released from a stratospheric helium balloon. While the deployment mechanisms activated correctly, and the overall sequence was completed, both main parachute canopies suffered damage.

Following hardware inspection, adaptations were implemented to the design of the parachutes and bags ready for the next high-altitude test, which was conducted on August 5, this time just focusing on the larger, 35m diameter, parachute.

A preliminary assessment has shown that the initial steps were completed correctly, however damage to the canopy were observed prior to inflation, similar to the previous test. As a result, the test module descended under the drag of the pilot chute alone.

“It is disappointing that the precautionary design adaptations introduced following the anomalies of the last test have not helped us to pass the second test successfully, but as always we remain focused and are working to understand and correct the flaw in order to launch next year,” said Francois Spoto, ESA’s ExoMars team leader.

All hardware, videos and recorded telemetries have now been recovered and are currently under evaluation. The analysis should reveal the root cause of the anomaly and will be able to guide the way forward in terms of further modifications that might be required to the parachute system before subsequent test opportunities.

A further high-altitude test is already foreseen for the first main parachute before the end of this year. The next qualification attempt of the second main parachute is then anticipated for early 2020.

In parallel, the teams are investigating the possibility to manufacture additional parachute test models and conducting ground-based simulations to mimic the dynamic nature of parachute extraction, since there are not many opportunities for full-scale high-altitude drop tests.

In addition to the regular forum of exchanges between ESA and NASA experts, a workshop of Mars parachute specialists will convene next month to share knowledge.

“Getting to Mars and in particular landing on Mars is very difficult,” added Francois. “We are committed to flying a system that will safely deliver our payload to the surface of the Mars in order to conduct its unique science mission.”

The ExoMars mission is scheduled for launch between July 25 and August 13, 2020, to arrive at Mars in March 2021. After driving off the surface platform, the Rosalind Franklin rover will explore the surface of Mars, seeking out geologically interesting sites to drill below the surface, to determine if life ever existed on our neighbour planet.

The rover is currently nearing completion at Airbus Defence and Space, Stevenage, UK, and will soon begin its environmental test campaign at Airbus Toulouse, France. At the same time, the flight carrier module comprising the descent module and lander platform will begin its final round of testing at Thales Alenia Space, Cannes, France. The rover will be integrated into the spacecraft in early 2020.

The ExoMars programme is a joint endeavour between ESA and Roscosmos. In addition to the 2020 mission, it also includes the Trace Gas Orbiter (TGO) launched in 2016. The TGO is already both delivering important scientific results of its own and relaying data from NASA’s Curiosity Mars rover and Insight lander. It will also relay the data from the 2020 mission once it arrives at Mars in March 2021.

Read more about the testing program for the ExoMars parachute here