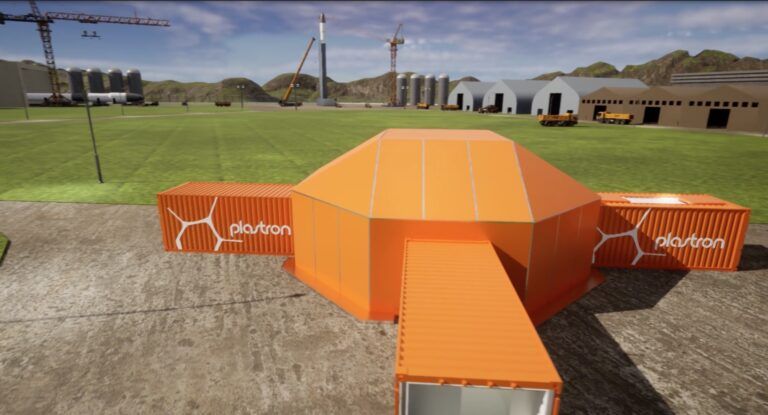

SaxaVord Spaceport in Shetland, Scotland is adding two clean rooms and an air lock for satellite payloard processing to its facilities.

The payload processing facility (PPF) is being built by space engineering safety specialists Plastron UK.

SaxaVord is developing a launch site and ground station in Unst, Shetland. The launch site at Lamba Ness is specifically designed for small rockets delivering payloads of up to 1,000kg into low earth orbit.

The first launch from Saxavord of an orbital satellite is planned to take place later this year. This will be the first working facility in the UK for launch vehicles with advanced payloads relying on propellants including hydrazine and LMP 103S.

Plastron UK has been commissioned to design, equip and deliver the PPF to enable satellites to be launched into space from Shetland.

Plastron, specialists in space engineering safety, has recently completed the design of Clean Room North, which will provide hazardous handling capabilities. They have now been further instructed to complete Clean Room South and the Air Lock.

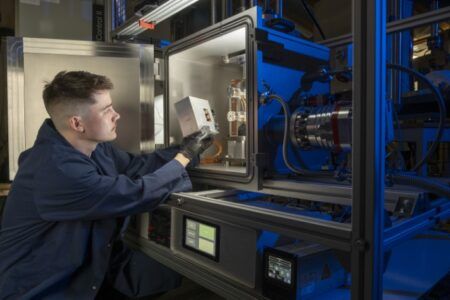

This program will include implementing Plastron’s HVAC system, which will ensure all cleanrooms are maintained at ISO8, a measure of very low particle concentration, at a fraction of the cost running conventional cleanroom air management systems.

The system was designed by Plastron with support from the academic research SPRINT program, applying leading fluid modeling expertise from the University of Southampton in the UK, and will be able to clean the SaxaVord cleanrooms down to ISO8 from atmospheric contamination levels in 15 minutes. Not only will this significantly reduce the energy consumption and running costs for SaxaVord, it will optimize launch campaigns by reducing the necessary downtime that occurs when flight hardware is unpacked and handled.

Chris Smith of Plastron said, “Using knowledge gleaned from performing launch operations throughout the world, we have designed the most advanced payload processing facility available for the New Space sector.

“The facility meets all expected European requirements for safe and efficient working environments for space hardware handling, and can tolerate all the hazardous risks associated with preparing payloads for launch. We are very excited to be working with SaxaVord to push this initiative forward.”

Scott Hammond, deputy CEO of SaxaVord, said: “These cleanrooms will give SaxaVord and the UK an unrivalled capability to host satellites of up to 1,000kg – no other spaceport will have this capability.

“This means we can host a multitude of different satellite sizes and that we are not restricted in our offering to the industry.