Testing in an AEDC space chamber at Arnold Air Force Base helped in preparing the Roll-Out Solar Array (ROSA) for its successful experimental deployment at the International Space Station on June 26 this year.

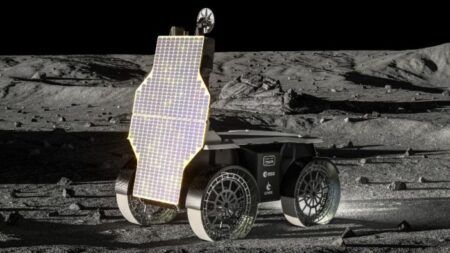

ROSA is a flexible, lightweight and rollable solar panel. According to Michael Malloy, AEDC test engineer and John Claybrook, AEDC Space and Missiles Combined Test Force test manager, who headed the test project for AEDC, ROSA is a newer type of solar panel that can roll open and is also more compact than other, more rigid, solar panel designs.

“Deployable Space Systems and Space Systems Loral initiated this technology for use in Space System Loral’s standard spacecraft bus for geosynchronous, or GEO, orbit,” Malloy said.

According to Malloy, the Air Force Research Laboratory and NASA also played a big part in the development by funding its advancement.

“What we did in the 7A Chamber was part of the thermal cycling of the solar panels,” Malloy said. “Because they’re thin in comparison with other solar arrays, we wanted to see how the testing in extreme heat and cold would affect it, and validate the cell bonding adhesives.”

ROSA was also tested in the AEDC space chamber for its gaseous helium capability. “This capability allows us to provide a 20 Kelvin background, which is -423°F (-253°C),” Malloy explained.

Additionally, the automated configuration facilitated US$209,000 of cost avoidance in test operations labor hours.

For ROSA, the chamber simulated 15 years of GEO in 121 days, getting down to -324°F (-197°C) and then ramping to 223°F (106°C).

“The benefit of ROSA is that the solar array is much more compact during launch, and the power to weight ratio is significantly increased over traditional rigid, legacy, solar panels,” Malloy said.

To verify on-orbit performance and functionality, ROSA underwent a week of tests on the end of the International Space Station’s robotic arm.