Researchers at the University of Texas at Austin are developing machine learning methods to reduce the amount of time it take to model and simulate rocket engines.

Computational simulations of rocket engines can take weeks or even months depending on the design and resources available. The researchers are working to significantly reduce this using an approach called scientific machine learning, which combines physics modeling with data-driven learning. The blend of data and modeling is used to create reduced-order models, simulations that can run in a fraction of the time and be used during design.

Karen Willcox, director of the Oden Institute for Computational Engineering and Sciences at the University of Texas at Austin said, “Rocket engineers tend to explore different designs on a computer before building and testing. Physical build and test is not only time-consuming and expensive, it can also be dangerous.”

But the stability of a rocket’s engine, which must be able to withstand a variety of unforeseen variables during any flight, is a critical design target engineers must be confident they have met before any rocket can get off the ground.

The cost and time it takes to characterize the stability of a rocket engine comes down to the sheer complexity of the problem. A multitude of variables affect engine stability, as do the speed at which things can change during a rocket’s journey.

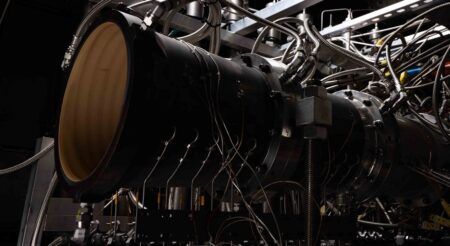

The new methods have been applied to a combustion code used by the Air Force known as General Equation and Mesh Solver (GEMS). Willcox’s group received “snapshots” generated by running the GEMS code for a particular scenario that modelled a single injector of a rocket engine combustor.

The snapshots represent the instantaneous fields of pressure, velocity, temperature and chemical content in the combustor, and are the training data from which the researchers derive the reduced-order models.

Generating that data in GEMS takes about 200 hours of computer processing time. Once trained, the reduced-order models can then run the same simulation in seconds. “The reduced-order models can now be run in place of GEMS to issue rapid predictions,” Willcox said.

But these models do more than just repeat the simulation, they also can simulate into the future, predicting the physical response of the combustor for operating conditions that were not part of the training data.

Although not perfect, the models do an excellent job of predicting overall dynamics. They are particularly effective at capturing the phase and amplitude of the pressure signals, key elements for making accurate engine stability predictions.

“These reduced-order models are surrogates of the expensive high-fidelity model we rely upon now,” Willcox said. “They provide answers good enough to guide engineers’ design decisions, but in a fraction of the time.”

Ramakanth Munipalli, senior aerospace research engineer in the Combustion Devices Branch at Air Force Rocket Research Lab said, “The reduced-order models will play an essential role in putting rapid design capabilities into the hands of our rocket engine designers.

“In some important cases, they are the only means by which one can simulate a large propulsion system. This is highly desirable in today’s environment where designers are heavily constrained by cost and schedule.”

The research is outlined in a recent paper published online by AIAA Journal. It is part of a Center of Excellence on Multi-Fidelity Modeling of Rocket Combustion Dynamics funded by the Air Force Office of Scientific Research and Air Force Research Laboratory.

This story is an edited version of a post originally published at the University of Texas at Austin website here.