Researchers in the USA and China have developed an artificial intelligence algorithm that improves the accuracy of plastic deformation measurements.

The algorithm, which was developed at Brown, Massachusetts Institute of Technology and Nanyang Technical University (NTU) in Singapore, vastly reduces the error rates involved in testing the mechanical properties of materials using instrumented indentation techniques. The process could also be particularly useful on evaluating modern 3D printed materials.

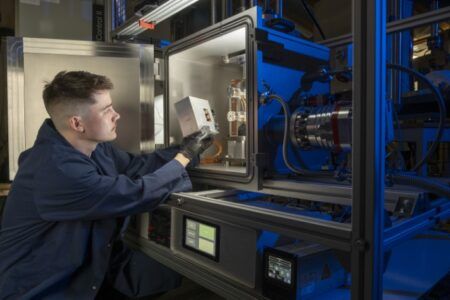

Instrumented indentation is a way of testing the mechanical properties of materials in a non-destructive way and involves measuring the forces required to make tiny dents in a material and then using those measurements to calculate material properties.

The technique works well for measuring elastic deformation, but not for plastic deformation, the forces that cause irreversible changes to a material. “The error rates using this technique for plastic properties had been on the order of 140%,” said George Karniadakis, a professor of applied mathematics at Brown. “But using this machine learning technique, we can bring that down to 4 or 5%.”

Multifidelity

The researchers used a set of neural network machine learning algorithms that are able to learn from data of varying quality. The “multifidelity” approach can combine lower-fidelity data from computer simulations of plastic deformation with data from direct experiments.

The experimental data is much higher in quality but is often scarce for a given material. By combining experimental data with simulation, the multifidelity algorithm needs only a handful of experiments to return reliable results.

The researchers also showed that a neural network that had been trained on one material could be easily adapted to a different material with minimal additional training.

“Normally it would take 10,000 iterations to train a network on a new material,” said Lu Lu, a postdoctoral researcher at Brown and the study’s lead author. “But we can use information from one material and transfer it to the new material with just a few experimental data points.”

Karniadakis says the new algorithms can be easily incorporated into existing instrumented indentation hardware. The researchers have patented the algorithms and plan to make them available commercially.

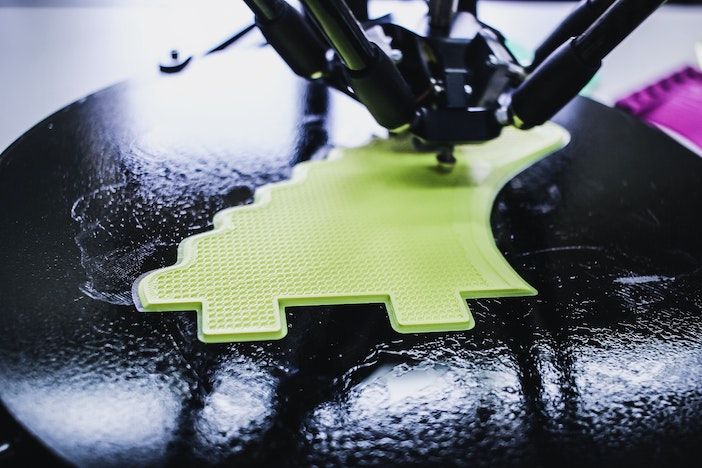

The new system could be particularly useful for evaluating materials made via 3D printing and other additive manufacturing methods, where experimental data on their properties is particularly scarce.

“Materials have to be carefully tested before they’re used, particularly in areas like the aerospace industry and other critical applications,” Karniadakis said. “As we move more toward 3D printing and other additive manufacturing, there’s a need to evaluate these novel materials, and this will help to do that.”

The research has been published in Proceedings of the National Academy of Sciences. Co-authors on the paper were Subra Suresh, a former Brown professor and National Science Foundation director who is now president of NTU, Ming Dao, Punit Kumar and Upadrasta Ramamurty.