A research program being led by Rolls-Royce in the UK is to develop miniature inspections tools, snake-arm robots and parts that repair themselves inside aircraft engines.

The miniature maintenance and inspection tools and new repair technologies will be used on Rolls-Royce’s existing engines such as the Trent XWB. Researchers on the Reinstate project will also work on inspection and repair solutions for the composite fan technology being used in Rolls-Royce’s next-generation engine design, the UltraFan.

In total engineers will work on 20 technologies that aim to reduce disruption for airlines and lessen the environmental impact of aircraft by repairing components rather than scrapping them.

Dr Ian Mitchell, chief of technology – repair and services, at Rolls-Royce, said, “This program will improve how we service our engines, creating technologies which will reduce waste, avoid emissions and minimise disruption, while laying the foundations to service the gas turbine and hybrid-electric engines of the future.”

The three year program, which is part-funded by the UK Government via the ATI (Aerospace Technology Institute) Programme, involves the University of Nottingham, the University of Sheffield, and the University of the West of England, as well as the companies Roke Manor Research, BJR Systems, Clifton Photonics.

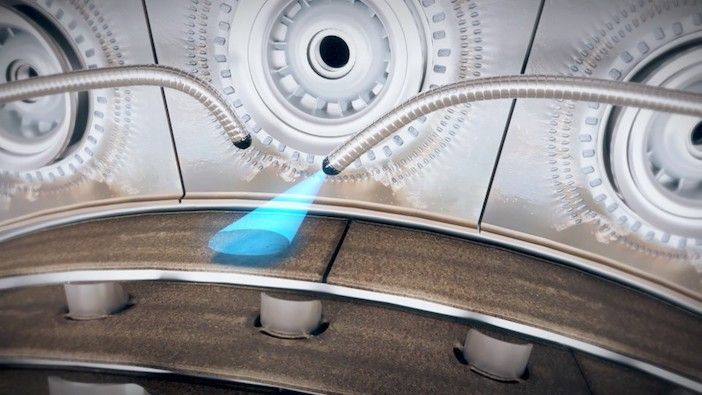

The University of Nottingham, researchers will support the development of the following technologies snake-arm robots that travel inside jet engines to access complex parts, enabling repairs which are not possible with today’s tools, inspection and analysis tools to inspect parts buried deep within engines while they are being repaired and automated repair technologies that target parts that cannot currently be repaired.

Professor Dragos Axinte, director of the Rolls-Royce University Technology Centre (UTC) in Manufacturing and On-Wing Technology at the University of Nottingham said, “Following an extensive track record of working with Rolls-Royce I am delighted that our team will continue to support an exciting research area which will help shape air travel for many years to come.

“The UTC at Nottingham brings together a range of skills which places us perfectly to support our industrial partners. The Reinstate initiative expands our capability significantly and I look forward to delivering new capabilities through the course of this project.”

Engineers at Roke Manor Research will lead on the development of algorithms that use data from engine installed inspection sensors to analyze and provide rapid in-service diagnostics.

Paul MacGregor, managing director of Roke said, “Focusing on our machine vision capabilities, we will help Rolls-Royce interpret and exploit the diverse data challenges to better predict when engines need maintenance.”