Researchers from the Technical University of Denmark have designed a fuel cell they say is light and powerful enough for aerospace applications.

The Monolithic Gyroidal Solid Oxide Cell or The Monolith for short delivers more than one watt per gram, broadening the field of possible fuel cell applications and addressing the challenge of their heaviness in aerospace applications, according to the researchers.

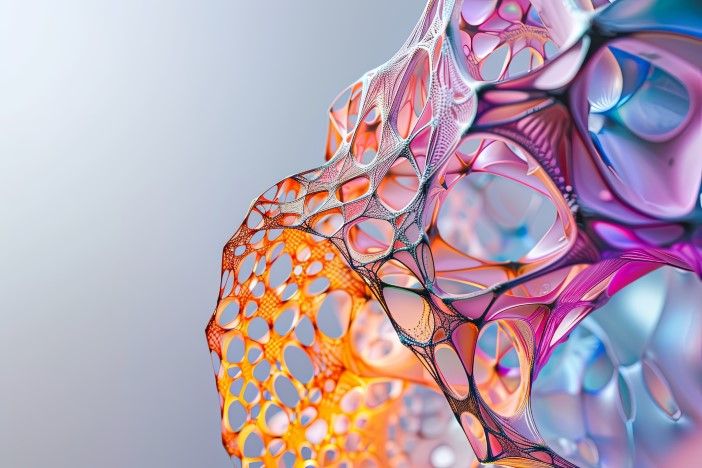

The solid oxide cells (SOCs) are produced using 3D printing and use a gyroidal geometry to create a structure known as a triply periodic minimal surface (TPMS), that is mathematically optimised for maximum surface area in a given volume and minimum weight.

Gyroid shapes are employed by engineers om heat exchangers and by nature in structures such as butterfly wings and coral. It is structurally robust and lightweight.

The researchers at Technical University of Denmark (DTU) have used the gyroid to make electrochemical conversion devices such as SOCs for the first time.

The study, which has been published in the journal Nature Energy. A patent was filed in 2024 to protect the concept.

Professor Vincenzo Esposito from DTU Energy, Senior Researcher Venkata Karthik Nadimpalli from DTU Construct, and several colleagues from both departments

Venkata Karthik Nadimpalli, a senior researcher at DTU Construct and an author of the study said, “Currently, electricity-based energy conversion, such as batteries and fuel cells, doesn’t make sense for aerospace applications. But our new fuel cell design changes that. It’s the first to demonstrate the Watts to gram ratio – or specific power – needed for aerospace, while using a sustainable, green technology,” he says.

Extreme resilience

As well as the weight being significantly reduced, the Monolith system allows gases to flow efficiently through the cell, improves heat distribution, and enhances mechanical stability. Switching to electrolysis mode, they produced hydrogen at nearly ten times the rate of conventional designs.

“We also tested the system in extreme conditions, including temperature swings of 100°C, and repeatedly switched between fuel cell and electrolysis modes. The fuel cells held up impressively, showing no signs of structural failure or layers separating,” says Vincenzo Esposito, corresponding author and professor at DTU Energy.

This kind of resilience is vital for space missions like NASA’s Mars Oxygen ISRU Experiment (MOXIE), which aims to produce oxygen from Mars’ carbon-dioxide-rich atmosphere.

This mission currently relies on bulky stacks weighing more than six tons. The new design could deliver a similar performance at 800 kg, which would significantly lower the costs of launching the equipment up there.

What makes this design especially compelling is not only its performance but also how it’s made, explains Venkata Karthik Nadimpalli:

“While conventional SOC stacks require dozens of manufacturing steps and rely on multiple materials that degrade over time, our monolithic ceramic design is produced in just five steps, where we eliminate the metal and avoid fragile seals,” he says.

“Still, I believe that we can improve the system further using thinner electrolytes, cheaper current collectors, like silver or nickel instead of platinum, and even more compact designs.”