Were the pressure vessel of NASA’s Orion spacecraft to fail during its next moon mission, its four-astronaut crew could spend up to six days exposed to hard vacuum. With this in mind, “You really need to look at materials performance and degradation over that long term,” says Dustin Gohmert, NASA’s Orion crew survival spacesuit project manager.

The last time a moonwalk spacesuit was used was in 1972, during the most recent Apollo mission to the moon, Apollo 17, but NASA has been working on returning Americans to the moon since a 2004 edict from the then president, George W Bush. Last December, President Donald Trump signed a policy that reconfirmed NASA’s commitment to manned missions to the moon in 2023 and then into deep space and Mars in the 2030s.

NASA is therefore pressing ahead with the development of spacesuits that will meet the demands of deep space missions to both the moon and Mars.

Operating under pressure

If, during that 2023 mission to the moon, the Orion spacecraft’s loss of pressure were to be rapid, the spacesuit would need to be inflated to double its typical pressurization.

“If we had a rapid depressurization of the cabin, we would actually take our suit to 8psi (55,158 Pa) for a few hours,” Gohmert says. After this time, the body would “naturally de-nitrogenate”, like a deep-sea diver, he adds. Once the risk of the astronaut experiencing the bends – nitrogen bubbles in the blood stream – had passed, the suit pressure would be lowered to 4.3psi (29,647 Pa). Human beings can breathe in pressure as low as this, as long as the gas around them is oxygen. The pressure of a spacesuit is kept that low in order to ensure that it remains flexible enough for the astronaut to be able to move.

Ian Meginnis, NASA advanced spacesuit development team engineer, leads a group focusing on exploration suits, for space walks or for working on the surface of the moon or Mars. For space walks from the International Space Station, NASA astronauts use the extravehicular mobility unit (EMU). The EMU suits have been on the space station for many years. In 2013, NASA awarded ILC Dover, the company which produced the suits used for the moonwalk, an 18-month contract to design, manufacture and test an alternative, the Z2 suit.

The Z2 is a technology demonstrator for surface activity and is capable of collecting soil and rock samples, and maneuvering in and out of moon and Mars habitats and crewed rovers. The suit operates at pressures higher than 4.3psi to enable extravehicular activity.

Higher pressures enable the introduction of inert gases such as nitrogen, reducing the flammability of the spacesuit interior. “We do pay attention to flammability,” Gohmert says. “But in a 100% oxygen environment, everything is flammable, including the human inside.”

To stop a fire breaking out inside the suit, NASA avoids the use of chemicals that have incompatibilities with oxygen, such as those made of hydrocarbons.

The agency also avoids energy sources, even a simple microphone. “We would tend to gravitate to a dynamic microphone that doesn’t require any external power instead of an electric microphone that needs a bias voltage. This minimizes the potential for any arcing of current,” Gohmert says. “That’s how we minimize any fire potentials.” A dynamic microphone uses the power of a person’s speech, the force of the sound striking the microphone’s membrane, to turn sound into an electrical signal, using electromagnetism.

And while science fiction films often portray future spacesuits with data projected onto the interior of the helmet visor, Meginnis says such electronics are too risky a proposition. “We really want to avoid putting high power electronics inside the helmet because it’s a flammable environment,” he explains.

A development in suit electronics that Meginnis does foresee is audible warnings. “We are interested in and looking at ways to incorporate caution and warning tones to give audible feedback to the crew.”

Exploration suits have a control unit display on the front that astronauts would use to control water temperature, audio levels, and other functions of its life support system. This is expected to be a feature of many future suits.

As well as higher pressures, the Z2 is partly made from composite materials, so it can be lightweight and durable while also providing protection from the harsh surface environment. The suit also has an adjustable shoulder and waist, to accommodate crew members of different sizes.

Dealing with body heat

NASA is also developing the Prototype Exploration Suit (PXS), a technology demonstrator with parts that could be 3D printed in space, on the moon or on Mars. The space agency has studied more efficient carbon dioxide removal and water evaporation systems for this project. Water evaporation systems are being developed for temperature control. These systems will help expel the heat generated by the human body and to keep the astronaut comfortable.

Gohmert says, “We’re stretching the boundaries of what we understand, specifically in the water loop that’s used for cooling the crew members. Those materials are undergoing quite a bit of testing.”

A major hurdle is developing biocides that can last a long time in the water loop. Biocides prevent biofouling of the water and inhibit corrosion of metal parts. The tubes that carry water can also leach out chemicals that may, “foul sublimators or gas traps or other equipment used in the cooling systems,” Gohmert explains. A gas trap is a membrane that can absorb and trap a gas’s bubbles. A sublimator is a device that can change a solid to a gas without it passing through a liquid phase.

“We have to be very careful with the water loop materials compatibility. Therein lies a vast majority of our testing,” Gohmert says. “Honestly, that’s a significantly deeper black hole to delve into than the suit materials themselves because they have such a good amount of history behind them.”

Those water loops snake through what is known as the soft goods – the materials that make up the bulk of the outfit. These consist of a Gore-Tex liner, a pressure bladder and a Nomex cover layer, similar to a flight suit. The helmet, not considered a soft good, is a fiberglass composite and the suit’s metal components are all typically 70% to 75% aluminum. All of these materials have a history of space flight use.

Unusually, the Orion spacesuit could have to endure days in vacuum, and be able to perform extravehicular activity such as space walks and surface exploration, so the traditional materials will still be used.

However, the Orion differs to the EMU and EVA (extra vehicular activity) suits in that it does not have a back pack, or Portable Life Support System (PLSS). Instead the PLSS functions are provided by the spacecraft. This also means that the only electronics in the Orion suit are the headphones and microphone.

For Orion, long umbilical cables provide the oxygen and take the carbon dioxide back to the spacecraft for scrubbing. “The vehicle scrubs the air, replenishing the oxygen that was consumed. It also provides the cooling water and the communications. Then that’s routed to the suit via the umbilical,” Gohmert says.

Shock and vibration tests

The astronauts do not have a PLSS with their launch and evacuation suits because they have to be fixed to the seat. Gohmert says, “The critical aspect of the crew survival suit is the seat interface, because every landing is somewhat of a controlled crash.” To help the astronauts cope, the seats are conformal and have five-point harnesses. “We spend a lot of time testing them,” he adds.

The suits’ components undergo vibration and shock testing. The shocking events include: parachute separation from the spacecraft, parachute deployment during atmospheric re-entry, and when the onboard motor fires to control direction “We look at the worst-case environment. Some of these shock loads are quite severe and the vibration environments are significant as well on launch,” Gohmert says.

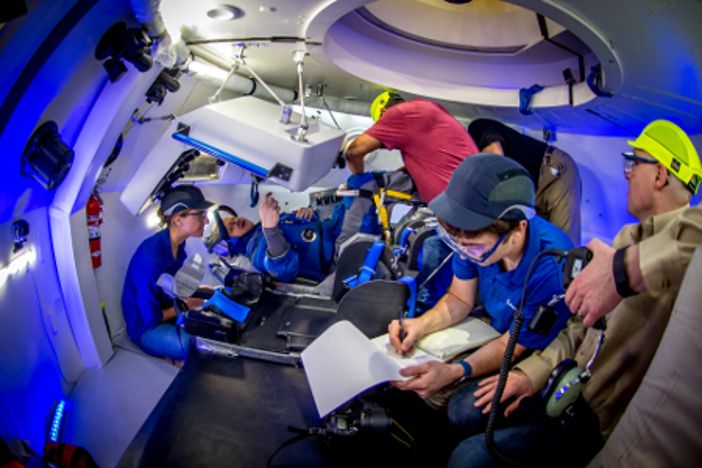

The Modified Advanced Crew Escape Suit’s life support system being tested at the Johnson Space Center (Photo: NASA/Bill Stafford)

Some spacesuit testing is more benign and focuses on the simple wear and tear of human use. Robots that can move joints through 0° to 90° have been used. Where suit joints use bearings, those are tested by rotating them for thousands or tens of thousands of cycles at different atmospheric pressures. “But more complex joints such as shoulders or hips would potentially need human testing to really evaluate the full range of motions and the strains put on them,” says Gohmert.

“You can look at a bearing. You can look at a hip, a joint, things like that, and cycle them separately,” Meginnis adds. “When you put them together, put a person in there and have them do work, that’s where you see a lot of different types of wear.”

Hidden dangers

Among the hidden sources of wear and tear on suit systems is radiation. The ISS astronauts operate within the Earth’s magnetic fields, which protects them from cosmic and solar radiation. Exploration of the moon and Mars will expose astronauts and their equipment to far higher levels of radiation. Spacesuit components must therefore be tested for their resilience to it.

“Any electronics we fly have to be extremely well vetted from radiation effects, from ionizing radiation, single event upsets and similar events,” Gohmert explains. “Electronics are commonly designed for terrestrial applications and aren’t designed to withstand those things. So, we spend quite a bit of time looking at those aspects, once we add more complex electronics to the situation.”

NASA has several different facilities around the USA that can and have provided radiation testing. Meginnis says that the Brookhaven National Laboratory in Long Island, New York, was recently used for this purpose. Such radiation testing can involve individual components or even the system itself.

Where a system is not tested for radiation tolerance, a probabilistic risk assessment is carried out. “A probabilistic risk assessment is where we add up the reliability of each one of the components, including its tolerance bands, to understand the worst-case effects of any specific failure along that chain. It’s a worst-case analysis,” Gohmert says.

Cosmic radiation, flammable atmosphere, extreme shocks and temperatures, vacuum, biocides, joint resilience, 3D printed parts – it’s a small wonder that the spacesuit is described by space agencies as a mini-spacecraft and considered almost as complex.

This article was originally published in Aerospace Testing International. To read it in the form it was originally published, and others like it, click here.