Capacitive sensors are used in billions of products to detect motion and sound. Virtually all of the two billion miniature microphones that are produced annually rely on capacitive sensing to convert the motion of a pressure-sensing diaphragm into an electronic signal.

Devices for sensing motion or pressure use a similar principle, but a lightweight and flexible compliant element is used, which moves when the slightest amount of force is applied to it.

The element has to be lightweight and flexible, so it moves easily. The motion of the element is transduced into an electronic signal by detecting the change in capacitance between it and a fixed electrode as it moves.

Unfortunately, to detect this change in capacitance, a bias voltage must be applied between the moving element and the fixed electrode. The higher the bias voltage, the more output signal is produced.

This bias voltage imposes a force on the moving electrode that can hinder its movement or cause it to collapse against the fixed electrode. Such sensors must therefore always have moving electrodes that are stiff enough to resist this imposed electrostatic force.

At the same time, the pressure sensitive diaphragm has to have enough stiffness to resist the attractive force of the electric field created by the bias voltage. The mechanical restoring force of the moving diaphragm must ensure the electrodes do not collapse into each other.

The diaphragm must also be flexible, so it can move, while remaining stiff enough to enable capacitive sensing. Designers don’t like to compromise between two opposing requirements, so we tried to find a new way to use capacitive sensing that avoids this conflict altogether.

To create a capacitive sensor that doesn’t result in adverse electrostatic forces being applied to the moving element, we devised a three-electrode arrangement. The approach completely avoids instabilities and minimizes the electrostatic forces.

Our recent results show that by including two fixed electrodes with one moving electrode, one can achieve negligible electrostatic stiffness while ensuring stability. This enables the long-sought goal of using electrostatic sensing with highly compliant and sensitive electrodes.

We used this electrode arrangement to create a microphone in which the diaphragm was as flexible as possible, enabling it to respond to tiny fluctuations in the air in a sound field. This capacitive sensing approach minimizes the influence of electrostatic forces.

The extremely compliant electrode may be used with bias voltages as high as 400V, without influencing its motion. Despite the use of a large bias voltage, our results demonstrate that the electric field does not result in stiffening or softening of the motion of the moving electrode.

The electric field has no noticeable effect on the response as a function of driving frequency. This electrode arrangement enables the use of very high bias voltages without adversely affecting the electrode motion, meaning an acoustic sensor could be created that has very high sensitivity of 0.5V/pascal, approximately 50 times that of conventional microphones.

While our initial study created microphones for audio frequency applications, this approach could also be used to create sensors for very low frequency sound (infrasound), as well as accelerometers and other motion sensors.

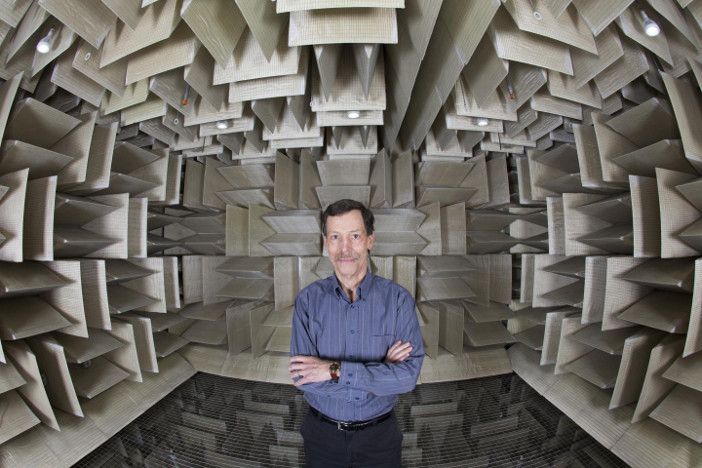

by Ron Miles, professor of mechanical engineering at Binghamton University, New York

This research was published in IEEE Sensors Journal 18.14 (2018), “A Compliant Capacitive Sensor for Acoustics: Avoiding Electrostatic Forces at High Bias Voltages” .