Gulfstream flew its latest model, the G400, for the first time on August 15, 2024. The aircraft lifted off from Savannah/Hilton Head International Airport and completed a 2-hour 54-minute sortie before landing. And so another next-generation Gulfstream model, the fifth in ten years, entered flight test, backed by the company’s R&D Center and Labs campus. Opened in 2006, the facility includes flight test laboratories and today encompasses more than 600,000 square foot while employing approximately 2,600 innovation and engineering professionals.

Vicki Britt, senior vice president, innovation, engineering and flight at Gulfstream, says, “The flight test labs Gulfstream uses today were developed for the next-generation Gulfstream fleet, which began with the G500 and G600, and now includes the G700, G800 and G400.

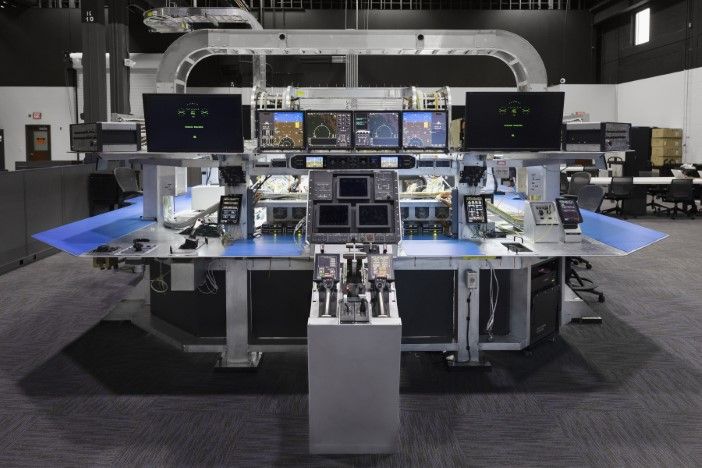

“The flight test labs include flight deck and cabin integration test facilities to develop and mature the integration of electronic system wiring and hardware and software – the iron bird, which tests flight control and mechanical systems, a conceptual advanced simulation environment to develop flight deck layouts and fly-by-wire control laws and conduct human factors evaluations. The labs also include a systems integration bench, which integrates avionics and aircraft systems with the aircraft’s data concentration network.”

The campus focuses on two primary areas beyond new aircraft programs. The labs continue their support to in-service aircraft as technology updates and new developments emerge and are tested before reaching the fleet, and they create and test future innovations. Facilitating all of this, the R&D campus includes facilities dedicated to acoustics and structural testing, extended reality, rapid prototype and additive manufacturing technologies, manufacturing techniques and technologies, environmental control systems, and advanced materials, plus the flight-test labs where aircraft undergo ground testing for development and certification.

Beyond requirements

Within the R&D environment, some lab elements would be familiar to past generations of aircraft engineers, including the fatigue test rigs. That familiarity might be superficial because Gulfstream goes one step beyond. Britt explains, “Like all aircraft manufacturers, Gulfstream performs full-scale fatigue tests to verify structural fatigue lives, validate structural inspection programs and ensure the safety of all passengers and crew. These trials begin before type certification to support entry into service and then continue for several years until completion.

“The aircraft structural inspection program – inspection locations, intervals and techniques – is determined by analysis, and computer modeling and provides a critical link between real-world test results and the data and assumptions used in the analysis. Digital twins of the fatigue test aircraft are used to understand the test results better and provide additional fidelity in the resulting analyses; strain gauge results from the test aircraft, for example, are directly correlated to stress levels in the digital twin. Additionally, periodic data reviews from our fleet ensure that the assumptions made in our test loading continue to be valid.”

Every new Gulfstream model is certified to FAA, EASA and other standards as customers in new regions emerge. Testing for compliance is expensive yet as far as regulation is concerned, Gulfstream goes well beyond the work required for certification. Britt responds to the question of why that additional investment is deemed worthwhile: “It’s part of our mission to pursue the utmost in safety and exceed expectations. By testing beyond requirements, we know that our aircraft can be certified to meet those requirements with absolute confidence and do so with an abundance of safety.

“Testing beyond requirements has also at times revealed that our aircraft perform beyond the initial estimates. The G500, G600 and G700, for example, demonstrated better performance in testing than we originally expected, and all of them were certified with longer range capabilities than when they were announced, to the great benefit of our customers.”

To those customers, and the world at large, every aircraft emerging from Savannah is simply a Gulfstream, yet each includes components large and small provided by other manufacturers. From an engine OEM delivering a complete integrated engine and nacelle, through to an avionics supplier building a flight deck and a cabinet maker supplying a cabinet door, all must meet Gulfstream’s exacting standards, adding to its test load.

Britt explains, “We work closely with suppliers to ensure their products meet our exacting standards and also have key supplier engineers embedded with our teams when necessary in the testing phase. In the labs, we can test and validate the functionality of software coming from suppliers and test all aircraft systems before first flight. We also create many components in-house – including cabinetry and furnishings, wings and nacelles for some models, giving us even more quality control and allowing us to integrate many of these elements into the testing phase.”

Britt mentions aircraft systems testing and Gulfstream is far from unique in the extent of testing it performs leading up to first flight. By the time a new aircraft’s wheels leave the runway on its maiden sortie it has already gone through thousands of testing hours as an iron bird, on a computer and in the simulator.

“Extensive ground testing in the labs makes a first flight even safer and more successful,” says Britt. “In the labs, we can amass thousands of simulated flight hours before the aircraft leaves the ground, ensuring the systems, including avionics and environmental controls, work as they should, and we can further optimize those systems in the labs before first flight. The lab testing also enhances efficiencies because we can achieve certification test points on the ground.”

The first flight is therefore largely a verification exercise compared to the exploratory nature of historic debuts. Does that mean the magic of achieving the first flight has been lost? Britt says not, while emphasizing that it also marks the end of one testing phase and the beginning of another in the labs.

“Making a first flight on a new aircraft is an exciting moment that instills pride in the team on the program and throughout the entire company,” she says. “Once flight test is underway, testing in the lab continues to help drive the efficiency of test flights – we can fly in the morning, analyze the data in the labs and make necessary updates the same day.”

simulated flight

Faster and safer

Due in no small part to its R&D efforts, today’s Gulfstream models are faster, more efficient, and safer than the aircraft they replace. While acknowledging the important role that the labs play in trialing new technology for in-service aircraft, Britt confirms that continuous improvement is a top priority, with teams dedicated to future technologies and safety advancements.

She illustrates the point by explaining the labs’ role in previous technology insertions: “Gulfstream’s enhanced flight vision system [EFVS] is just one example. We continue to enhance our EFVS system, which was first introduced on the GV. With the G500 and G600, Gulfstream was the first original equipment manufacturer to earn FAA certification allowing operators to use EFVS to dispatch and begin instrument approaches in low-visibility conditions.

“We then obtained the same certification for additional in-production and out-of-production aircraft so our customers could take advantage of this safety enhancement.

“For the G700 and G800, we took our flight deck innovations even further, adding our combined vision system [CVS] on dual head-up displays [HUD]. With the CVS, Gulfstream’s EFVS and synthetic vision system are overlain on the HUD, providing enhanced pilot situational awareness. The labs have been instrumental in our efforts to enhance this technology.”

A handful of forward thinkers see the relationship of the business aviation niche to the wider aviation industry as akin to that of Formula 1 to the automotive industry. Safety enhancements, like the HUD technology Britt is so proud of, typically first find their commercial application in business jet cockpits, while business jet owners and operators were early adopters of sustainable aviation fuel. This pioneering spirit relies upon a mix of practical engineering and blue-sky thinking, where OEMs accept that at least some of their R&D budget must be spent allowing the imaginations of designers and engineers to visit places yet unknown.

It is a philosophy Gulfstream embraces. Britt reveals, “We always have engineering teams dedicated to researching new and future developments, and they work hand-in-hand with the engineers working on current aircraft design, industrial design and flight deck systems.

“Thanks to General Dynamics, Gulfstream’s parent company, the investments we have been able to make in R&D have led us to create what we consider to be the most advanced fleet in the industry.”

People are the key element in R&D and labs like Gulfstream’s require a mix of experienced heads and new thinking. In an era where suitably equipped and qualified personnel are difficult to find and equally tricky to retain, how does Gulfstream staff a Research and Development Center and Labs campus that requires engineers with decades of experience and graduates with heads full of new ideas?

Confirming this approach, Britt continues: “We have engineers who have been with the company for decades and others who have just joined us.

“We attract many new engineers through our extensive internship and co-op programmes, which bring students from around the world. We also actively recruit across college campuses and military bases.

“We value the perspectives our diverse group of engineers brings and believe they have a positive impact on Gulfstream’s culture of innovation.”