“Every customer this fiscal year has a portion of their test matrix that is using Mach 18,” said John Lafferty, Tunnel 9 technical director. “They have been waiting for this.”

Prior to the calibration of Mach 18, the maximum speed offered at Tunnel 9, or at any AEDC facility, was Mach 14. Customers needing results at higher Mach simulations would be required to extrapolate the Mach 14 test conditions to the higher Mach numbers.

“This allows them to build their aero database with more confidence at the high end of Mach numbers,” Lafferty said.

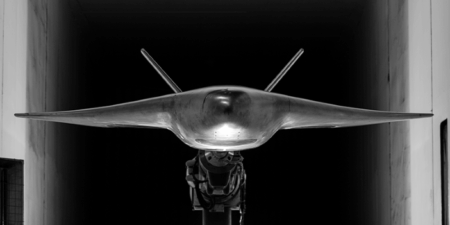

Wind Tunnel 9 can also be used for development of hypersonic reentry systems and boost glide concepts.

The Mach 18 capability is the result of decades of R&D, with calls for a wind tunnel capable of high hypersonic speeds dating back to the 1980s. However, early methodologies to design the nozzle and diagnostics systems to examine the physics of the flow proved immature. Because the flow quality of the nozzle was poor, the design was scrapped.

By the time higher Mach Number hypersonics again became a priority in the mid-2000s, computer-based modeling and simulation and diagnostic technologies had greatly advanced. A team was assembled at Tunnel 9 and a program aimed at achieving these higher Mach Numbers was designed.

Initial risk reduction efforts began in 2014 and focused on developing a new material for the nozzle, new laser diagnostics to verify the understanding of flow physics, and a new nozzle contour based on this understanding.

The US$6.5 million, three year long upgrade to Tunnel 9 was started in 2017. The upgrade project also received additional funding from the Hypersonic Test Capability Improvement Project.

The nozzle design and fabrication, the successful incorporation of the new nozzle throat material, and the diagnostic demonstration all occurred within the three-year timeframe and were completed within budget and on-schedule.

“Successfully completing this project required the coordination of multiple, separate, highly-technical efforts,” said Nicholas Fredrick, Tunnel 9 chief engineer.

An initial calibration using the final Mach 18 hardware occurred in April 2019. By the middle of that year, there had been several test entries at Tunnel 9 to demonstrate the feasibility of the Mach 18 capability. These tests helped determine whether the new nozzle throat material could survive and remain shape-stable at both Mach 14 and Mach 18 nozzle supply conditions and validate the Mach 18 nozzle with the new nozzle throats at the design condition.

More work followed, leading up to the full-calibration completed last year.

“Initial testing of the new Mach 18 capability revealed deficiencies in the high-press, high-temperature nozzle throat section design,” Fredrick said. “Data from the first entry was analyzed by AEDC engineers and subcontractors and design revisions were analyzed and subsequently implemented prior to the start of the second test entry.”

According to Lafferty, throughout the process of bringing Mach 18 to fruition, Tunnel 9 personnel gained knowledge that could be used to enhance other capabilities.

“This development has forced us to better understand our system and the resulting flow physics,” Lafferty said. “Our understanding of the flow physics is much improved and, thus, the resultant flow quality is outstanding. The potential exists to apply the lessons learned to a new Mach 14 nozzle with improved flow quality that will provide lower uncertainties for our customers.”

“The most satisfying thing is that customers are using it, and not just one or two. The first four customers following the calibration all are using it. We never anticipated that.”