The testing and deployment of laser weapons is of massive importance to future air defenses. The UK plans to install its first laser directed energy weapon, DragonFire on a Royal Navy ship in 2027.

In this Q&A the director responsible for the DragonFire program at MBDA UK describes how a laser directed energy weapon (LDEW) is tested, the milestones achieved so far and the next challenges.

Q: How does DragonFire work?

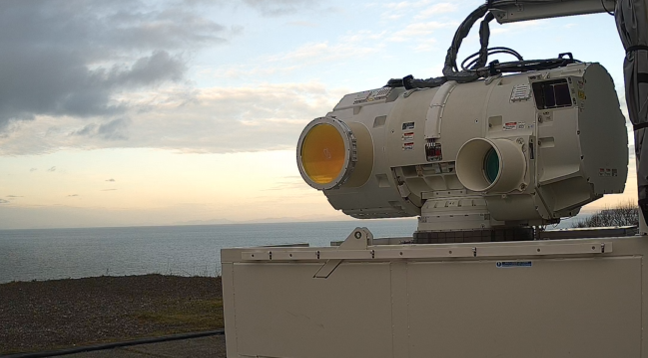

A: DragonFire is a laser directed energy weapon that uses three apertures on its beam director to search, identify and assess potential threats. The first apertures act like a pair of binoculars, searching for threats in a wide area.

Once a potential threat has been located the system then looks at the target through a second middle-range aperture providing more detail. The final aperture acts like a telescope, and on the beam director looks like one. It narrows in on the target assessing whether there is a threat or not, and if there is it provides ultra-precision targeting.

The beam is produced by taking raw electrical power, squeezing it down to create the laser source, then focusing and stabilizing that high-powered beam through the use of the latest hardware and advanced algorithms, and critically, targeting it so it is accurate and all that energy ends up precisely on the target.

That intense beam of light then cuts through the target defeating it.

Q: What is the most advanced part of DragonFire?

A: Getting the laser energy to the target has always been the real challenge. The sophisticated ways used to overcome atmospheric turbulence and keep the beam focused precisely on a moving target many kilometers away are the most important parts of the system.

Q: What is MBDA UK’s role on DragonFire?

A: MBDA UK is the prime contractor. We are producing the command and control system, the effects management system and handling the systems engineering and integration. This means making sure the various parts of the system go together as they should and that it satisfies the requirements as set out by our customer, including testing and verification.

Q: What kind of testing is required for a directed energy weapon?

A: Weapon effectiveness is multi-faceted for directed energy weapons. This is a hugely complex and subtle topic, requiring knowledge of cutting-edge physics across many disciplines.

On the one hand, you have target vulnerability and lethality. Targets are varied and made of different materials with different surface properties – getting laser energy efficiently into the target requires a good understanding of where targets are vulnerable and a detailed understanding of laser-matter interaction.

The basic approach is to take many samples of all the known target materials and subject each one to laser irradiation in various regimes, then carefully measure the time evolution of a particular damage mechanism. This is very slow and resource-intensive, so improving multi-physics modeling and attempting to reproduce such tests in simulation is always ongoing, but there are many coupled effects to capture and the parameter space is enormous.

On the other hand, you have weapon performance. How much laser energy can reach a vulnerable target spot depends on the complex and capricious nature of the atmosphere, as well as the precise functioning of all the various tracking, stabilization, and correction feedback systems.

Understanding turbulence and weather effects on propagation is a large part of testing. The measurement of turbulence itself is still a topic of active research. While theories exist to capture some of these effects, they are often based on approximations that don’t hold up in real-life conditions or don’t extrapolate well to parts of the world where such weapons might be deployed.

Some propagation tests are carried out with specialist instruments such as scintillometers directed across representative environments, often for months or years to build up statistics – but these are limited to a single geographic location. Other organizations have even launched formations of drones carrying ultrasonic anemometers in an attempt to characterize the altitude variation of turbulence. All these sorts of tests help us improve and validate performance models.

There is no substitute for a complete end-to-end test of the real high-power beam over a representative distance directed at a real flying thing – however, this requires enormous amounts of preparation and extensive safety measures. Such trials are also still limited to that one geographic location, the weather conditions that happen to occur, and the flying thing on that day – there is no way to get a good appreciation of statistical variation without astronomical expense.

Each of these tests, whether performed by us, our partners, or external organizations, only contributes a small piece of the jigsaw of weapon effectiveness across many possible scenarios in a complex battle setting. Our job is therefore to sift these data and build up the best picture possible.

Q: What testing facilities and equipment are used?

A: Subsystems are tested in the laboratory wherever possible, using various emulators or simulated environments. Target vulnerability studies are conducted in lab settings using representative laser sources rather than the real system.

High-power test firings can be done in the lab, but there are not many materials that can survive this amount of laser irradiance for long at close range, so the challenges are significant. In general, operating very high-power lasers in a laboratory is orders of magnitude easier than outside, but due to the lack of atmospheric propagation distance, a lab environment cannot ever test the full performance of the system. However, Laser beams do not stop until they hit something, thus, the process to test DragonFire ‘above the horizon’, as captured by the now famous photograph, marked the most significant milestone in its development history.

Q: What has been the most challenging aspect of developing DragonFire so far?

A: There are many technical challenges – but that is what is particularly exciting about developing something new like DragonFire. If I look at it from a testability perspective, then elements that benefit from full system testing in the real world are particularly challenging.

For example, designing a target tracking system that can robustly maintain the position of the spot-on target is, without doubt, the biggest challenge. As the target heats and starts to give off smoke and particles, this can cause its optical signature to change significantly.

Even with advanced cameras in multiple bands and sophisticated image processing algorithms operating at thousands of frames per second, keeping to the desired precision – the equivalent of hitting the center of a pound coin a kilometer away – is hugely challenging.

Q: What are the safety considerations when testing?

A: While testing a missile also requires significant safety considerations, what makes Laser Directed Energy Weapon (LDEW) systems unique is the extreme range over which a safety hazard can exist. This represents a much larger potential risk area than most weapon tests.

This extended hazard range means that approval of the safety case and implementation of the associated risk mitigation measures always represent a significant effort and major milestone in any high-power DragonFire trial.

Q: What will operational trials for DragonFire entail?

As DragonFire is a novel weapon system, a large part of operational trials focus on understanding and communicating the important differences between it and other weapon systems – its advantages and limitations. This means, for example, testing in a wide variety of conditions. This sort of trial is essential to define weapon effectiveness and help users build up a good picture of how DragonFire fits in with other layers of defensive weapon systems as part of the larger battlespace.

Q: What are the immediate challenges of installing DragonFire on ships?

A: The next challenges are location, size, and robustness. Current Royal Navy ships were not designed with LDEWs in mind and locating them on board requires a trade-off. They need to retain a firing arc as wide as possible to be useful, but also not get in the way of extant equipment.

Additionally, they must be serviceable by power, cooling, etc. We are also shrinking the weapon system down to fit within a defined footprint. Shaving off every cubic centimeter possible from internal systems without causing major design changes.

The final aspect is working on ruggedizing the system for long-term operation at sea. Ensuring the system will be robust to shock and vibration, and that the precision optics required survive the elements experienced in a maritime environment.

Q: How does weather impact performance?

A: As mentioned previously, laser weapons are affected by the atmospheric environment.

Mitigation of atmospheric effects is currently done in two ways – simply delivering more power to compensate for worse conditions and attempting to correct as much of the atmospheric wave-front distortion as possible.

The latter, more subtle technique involves a great deal of engineering. Precisely measuring the very small return signal from an uncooperative target of unknown reflectivity and surface finish, working out the optimal correction to the beam to undo atmospheric distortion, and doing this all with sufficient speed to cope when slewing the beam through a changing atmosphere tracking a high-speed target.

This is where DragonFire excels – and allows us to offer the highest possible effectiveness without needing to overcompensate by going to such high powers that issues such as thermal blooming start to dominate (a nonlinear interaction caused by the beam heating the air that causes it to diverge before it can reach the target).

Q: Are there any new skills needed to develop LDEWs?

A: Lasers have been around for decades, so they are not a new skill. Weaponizing them is probably a newer skill, but at MBDA, we are leaders in the field of complex weapons and so our expertise, and those of our partners Leonardo and QinetiQ, are what has enabled the development of DragonFire.

As a rapidly evolving program, DragonFire uses the skills of engineers from various disciplines, including Systems Engineering, Systems Design, Equipment Design, and Integration & System Validation. With LDEW being an emerging technology, the key characteristics needed, and what we look for in a skill-set, is a keenness to learn and a willingness to incorporate a dynamic approach to the work.

What is new with LDEW as we progress to a deployable capability, is how the capability is operationally used. This is why we are working with the Royal Navy to understand the best way to do this and therefore train future operators effectively.

Q: Will technology developed for DragonFire be suitable for use in other systems?

A: Because LDEW requires such precision beam alignment, it also requires a high-quality precision stabilized, high-zoom optical observation system working in multiple bands. This means that the technology developed for DragonFire targeting and tracking could be useful in threat identification and targeting for future weapon systems.

Q: What are the benefits of directed energy weapons?

A: They offer a deep magazine and low cost-per-shot. DragonFire can keep firing as long as there is power. This is of ever-increasing importance in the era of asymmetric drone warfare.

As a line-of-sight weapon, they operate best as an additional layer within Integrated Air and Missile Defence and a complementary effector to traditional defensive systems such as guns and missiles. As targets become faster the range coverage required of DEWs is expanding, and awareness and mitigation of DEW vulnerabilities within adversaries is also improving, so DEW power and range envelope is always being pushed.

Q: How else will future LDEW systems improve?

A: As mentioned above, the power-range envelope is constantly being expanded for LDEW. However, another big focus is on the size and weight of LDEW, so that effective, high-power systems can be fielded on mobile land and even air platforms.

So, improving laser source power density and efficiency is crucial, as well as miniaturization of other elements such as beam combining and directing optics and supporting infrastructure such as thermal management and power buffering solutions will be an area of focus for MBDA in future systems.

Finally, improving the effectiveness of LDEW systems by improving and then leveraging an understanding of target vulnerability to this class of weapon system will ensure maximum effect regardless of domain.