Researchers at the FAMU-FSU College of Engineering in Florida, USA have designed a liquid hydrogen storage and delivery system that could enable zero-emission aviation by addressing multiple challenges in electric-powered aircraft. Their work outlines a scalable, integrated system that uses hydrogen as both clean fuel and cooling medium for critical power systems.

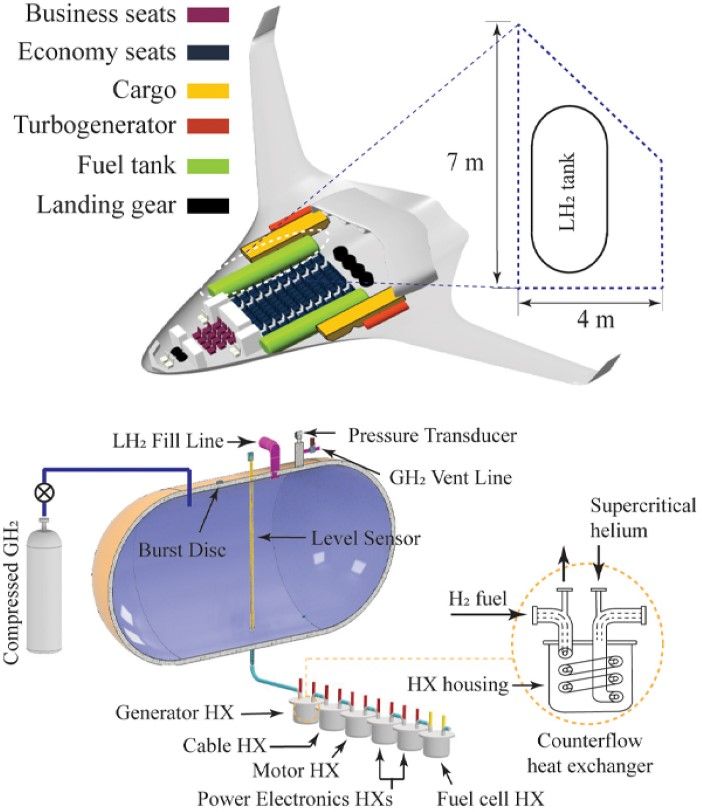

The study, published in the journal Applied Energy, introduces a design tailored for a 100-passenger hybrid-electric aircraft that draws power from both hydrogen fuel cells and hydrogen turbine-driven superconducting generators. The system shows how liquid hydrogen can be efficiently stored, safely transferred and used to cool onboard systems while supporting power demands during takeoff, cruising, and landing.

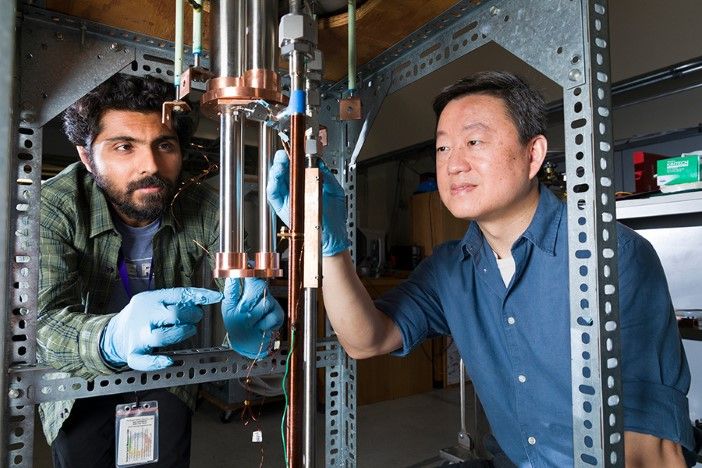

“Our goal was to create a single system that handles multiple critical tasks: fuel storage, cooling and delivery control,” said Wei Guo, professor in the department of mechanical engineering and corresponding author of the study at FAMU-FSU. “This design lays the foundation for real-world hydrogen aviation systems.”

Hydrogen as an aviation fuel has the advantage that it contains more energy per kilogram than jet fuel and emits no carbon dioxide. However, it has the disadvantage that it requires storage as super-cold liquid at -253°C (-423°F) due to its low density compared to conventional fuels.

The team from FAMU-FSU, which is the joint engineering college of Florida A&M University (FAMU) and Florida State University (FSU) +conducted system-level optimization to design cryogenic tanks and associated subsystems. Instead of focusing solely on tank design, they defined a new gravimetric index representing the ratio of fuel mass to total fuel system mass, including hydrogen fuel, tank structure, insulation, heat exchangers, circulatory devices and working fluids.

By adjusting key design parameters such as vent pressure and heat exchanger dimensions, they identified the configuration yielding maximum fuel mass relative to total system mass. The optimal configuration achieves a gravimetric index of 0.62, meaning 62% of the system’s total weight is usable hydrogen fuel.

The system’s thermal management function routes ultra-cold hydrogen through heat exchangers that remove waste heat from onboard components including superconducting generators, motors, cables and power electronics. As hydrogen absorbs heat, its temperature rises, which is necessary since hydrogen must be preheated before entering fuel cells and turbines.

To avoid complexity and weight of mechanical pumps under cryogenic conditions, the team developed a pump-free system using tank pressure to control hydrogen flow. Pressure is regulated by injecting hydrogen gas from high-pressure cylinders to increase pressure and venting hydrogen vapor to decrease it.

A feedback loop links pressure sensors to the aircraft’s power demand profile, enabling real-time adjustment of tank pressure to ensure correct hydrogen flow rates across flight phases. Simulations show the system can deliver hydrogen at rates up to 0.25 kilograms per second, sufficient to meet 16.2-megawatt electrical demand during takeoff or emergency go-around.

The heat exchangers operate in staged sequence, with hydrogen first cooling high-efficiency components operating at cryogenic temperatures, such as high-temperature superconducting generators and cables. It then absorbs heat from higher-temperature components including electric motors and power electronics before being preheated for fuel cell inlet conditions.

“Previously, people were unsure about how to move liquid hydrogen effectively in an aircraft and whether you could also use it to cool down the power system component,” Guo said. “Not only did we show that it’s feasible, but we also demonstrated that you needed to do a system-level optimization for this type of design.”

The next phase involves experimental validation, with Guo’s team planning to build a prototype system for testing at FSU’s Center for Advanced Power Systems. The project is part of NASA’s Integrated Zero Emission Aviation program, bringing together institutions across the US including Georgia Tech, Illinois Institute of Technology, University of Tennessee and University at Buffalo.

This article edited from the original published by Florida State University