The CMF panel after the test. The black marks are fragments trapped inside the panel. (Image: NC State University)

Researchers have successfully shown how steel composite foam offers better protection than existing armor from anti-aircraft rounds, while also weighing less, in a series of tests and simluations.

The researchers, from North Carolina State University and the US Army’s Aviation Applied Technology Directorate, fired high explosive incendiary (HEI) rounds, the type often used in anti-aircraft weapons, into stainless steel composite metal foam (steel-CMF) and detonated them only 18in (450mm) away.

The steel-CMF successfully blocked the blast pressure and fragmentation at 5,000ft/sec from the HEI rounds.

Afsaneh Rabiei, senior author of the study and professor of mechanical and aerospace engineering at North Carolina State University said, “We found that steel-CMF offers much more protection than all other existing armor materials, while lowering the weight remarkably.

“We can provide as much protection as existing steel armor at a fraction of the weight – or provide much more protection at the same weight.

For the test, researchers fired a 23 × 152mm HEI round into a 2.3mm-thick aluminum strikeplate. Steel-CMF plates of either 9.5mm or 16.75mm thickness were placed 450mm from the aluminum strikeplate.

The researchers assessed that the steel-CMF held up against the wave of blast pressure and against the copper and steel fragments created by the exploding round, as well as aluminum from the strikeplate.

“Both thicknesses of steel-CMF stopped the blastwave, and the 16.75mm steel-CMF stopped all of the fragments sizes,” Rabiei said.

“The 9.5mm steel-CMF stopped most, but not all, of the fragments. Based on the results, a 10mm steel-CMF plate would have stopped all of the fragment sizes.”

“Many military vehicles use armor made of rolled homogeneous steel, which weighs three times as much as our steel-CMF.

“Based on tests like these, we believe we can replace that rolled steel with steel-CMF without sacrificing safety, better blocking not only the fragments, but also the blast waves that are responsible for trauma such as major brain injuries. That would reduce vehicle weight significantly, improving fuel mileage and vehicle performance,” Rabiei added.

Model simulation

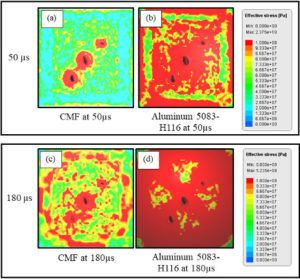

Comparison of the stress distribution in CMF (a,c) and aluminum 5083-H116 (b,d) panels upon interaction with blast wave and fragment impacts

The researchers also developed computer models of how the steel-CMF plate would perform as part of the study. When compared to the experimental results, the model matched very closely. The researchers then used the model to predict how aluminum 5083 armor – a type already on the market that has a similar weight and thickness to the 16.75mm steel-CMF – would perform against HEI rounds.

The model showed that, while aluminum armor of similar weight to the steel-CMF panels would stop all of the fragments, the aluminum armor would buckle and allow fragments to penetrate much deeper. This would result in more damage to the panel, transferring large amounts of stress to the soldiers or equipment behind the armor.

On the other hand, the steel-CMF absorbs the energy of the blast wave and flying fragments through local deformation of hollow spheres, leaving the steel-CMF armor under considerably less stress – offering more protection against fragments and blast waves.

Engineers will next test the steel-CMF against improvised explosive devices and high-caliber, mounted ballistics. The researchers have already tested the CMF’s performance against hand-held assault weapons, radiation and extreme heat.

The research paper, “A study on blast and fragment resistance of composite metal foams through experimental and modeling approaches,” was published last month in the Journal of Composite Structures.

April 11, 2018