Metrology company Hexagon is making its modelling software available to additive manufacturing firm Stratasys’ aerospace customers to help reduce the time it takes to design and test a part.

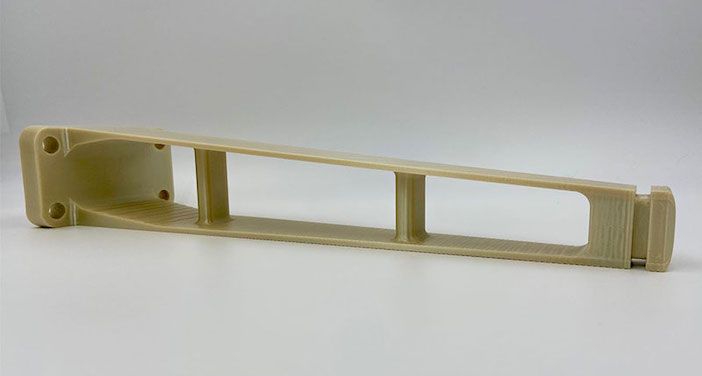

People who are printing with additive manufacturing (AM) machine-maker Stratasys’ ULTEM 9085 thermoplastic resin will be able to use Hexagon Manufacturing Intelligence’s Digimat material modeling software to reduce part lead time for certifiable aerospace parts. ULTEM 9085 can be used to produce parts for aircraft cabin interiors, such as bracketry, pieces for cable routing, covers and duct components to certified standards around flammability and toxicity.

OEMs such as Airbus and suppliers such as Diehl Aviation have used additively manufactured parts in aircraft cabin interiors for several years. According to Hexagon, use of the Digimat software can reduce a two-to-three-year timescale for designing and testing a part to six-to-nine months by helping to predict how printed parts will perform mechanically when printed with two compatible printers.

This is made possible through a highly accurate virtual material model jointly developed by the two companies through physical testing that includes detailed information about the material’s internal microstructure.

The Digimat software’s process simulation capabilities help manufacturers avoid defects such as the delineation of warpage of a part and analyze the print time and material cost to achieve an optimal result.

Guillaume Boisot, head of ICME for Hexagon’s Manufacturing Intelligence division said, “The aerospace industry is continuously pushing the boundaries of performance and innovation, but current confidence in the performance of additive manufactured parts is mostly limiting its application to highly specialized metal parts.

“We are excited that this new development in our partnership with Stratasys will help compress the design and testing phases and improve understanding of plastic behavior and speed up innovation across the sector.”

Scott Sevcik, vice president of the aerospace business segment for Stratasys said, “The dual needs to make complex parts lighter and produce low volumes economically has meant that aerospace has pulled 3D printing towards production and put the sector ahead of the curve in use of the technology.

“But this also means it’s the first industry to identify several challenges, a key one being the need for a digital toolset to provide confidence in 3D printed parts. Our partnership with Hexagon is a big step forward in solving that, as it gives engineers the same upfront design intelligence for 3D printing that they have for traditional processes.”

The virtual engineering solution can now be accessed by customers of the Digimat material modelling software. Stratasys customers can request access to detailed proprietary material cards through its Materials Exchange capabilities and import toolpaths directly from their Stratasys Insight software.