Ultraviolet radiation is used in fluorescent penetrant and magnetic particle non-destructive evaluation methods to fluoresce materials used to indicate the presence of flaws in safety critical components. This is especially the case for components used in the aviation, space, and automotive sector. The specific radiation that is used in these tests is governed by ASTM E3022 and Rolls Royce 90061 and has a wavelength of 365nm + or – 5nm. This specific ultraviolet radiation wavelength allows operators to work safely while performing inspection using standard personal protection equipment.

The process of creating Ultraviolet (UV-A) radiation has evolved over the years and today the use of instant-on LED technology is prevalent in industry. Operator efficiency, operator safety, and environmental safety are maximized using LED UV-A technology. The use of LED UV-A lamps implements a number of safety advantages compared to other methods, such as low temperature housings, low voltage circuit design, lightweight design and the elimination of the use of mercury.

Low voltage DC electrical energy, 18-24 volts, is high enough to produce LED UV-A luminescence. This voltage can be produced by battery power or by a wall outlet. This is a tenth of the voltage required by other technologies used in the past.

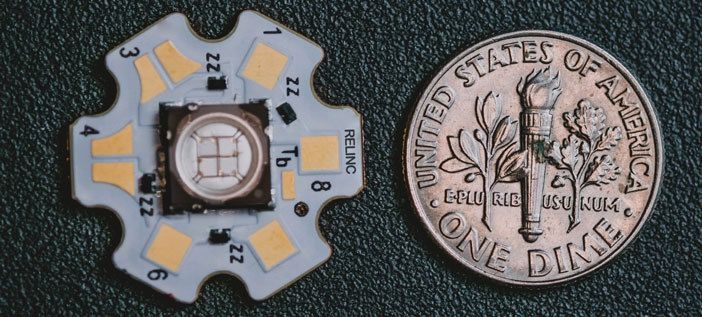

Filaments that operate at temperatures of thousands of degrees in a vapor of mercury have been eliminated using LEDs. This means that skin burns caused by accidentally bumping the light and the hazardous waste streams from the disposal/breakage of bulbs have been eliminated. LED’s are also small components with high energy output. The result is smaller and lighter packaging, which directly results in a reduction of repetitive motion injuries to operators.

However, the challenge with smaller higher energy technology integration into the light is controlling the heat around the LED emitter. Around 30% of the electrical energy input to the emitter goes to producing luminous flux. This means 70% is waste heat that must be controlled to keep the emitter at a maximum of 140˚F or there will be deleterious effects on emitter life. Design approaches that ensure high heat flux in the lamp body include using materials that have high thermal conductivities like aluminum and copper, minimizing the number of internal contact resistances and maximizing the surface area to transfer heat to the surrounding environment.

In addition to thermal design considerations, mechanical energy from abusive treatment in service needs to be included in the base design of a LED lamp. The LED technology is robust and can survive drops which produce hundreds of g’s. Therefore, the connection system of the LED emitter needs to be designed to isolate the LED from drop events that happen in the workplace daily.

Safe, long functioning tools like LED Lamps will continually be developed to maximize the utility of LED technology in non-destructive testing. Non-destructive evaluations with LED technology will maximize safety for travel here on Earth and beyond.

This article was provided by REL