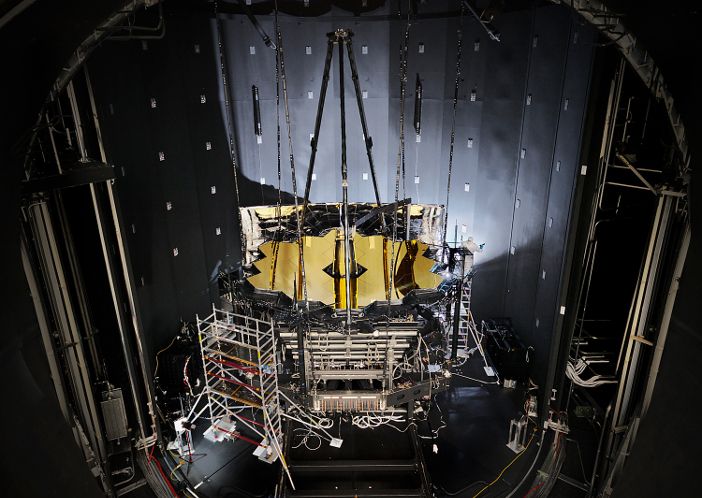

The unsealing of the 40ft-diameter, 40-ton door of Chamber A at NASA’s Johnson Space Center in Houston, Texas, marked the end of about 100 days of testing for the James Webb Space Telescope (JWST).

The cryogenic vacuum test had begun when the chamber was sealed on July 10. Webb’s optical telescope and integrated science instrument module (OTIS) was put through a series of tests designed to ensure the telescope functioned as expected in an extremely cold, airless environment simulating that of space.

“After 15 years of planning, chamber refurbishment, hundreds of hours of risk-reduction testing, the dedication of more than 100 individuals through more than 90 days of testing, and surviving Hurricane Harvey, the OTIS cryogenic test has been an outstanding success,” enthused Bill Ochs, project manager for the James Webb Space Telescope. “The completion of the test is one of the most significant steps in the march to launching Webb.”

There was also an alignment check of Webb’s 18 primary mirror segments, to ensure all of the gold-plated, hexagonal segments acted like a single, monolithic mirror. This was the first time the telescope’s optics and its instruments were tested together, though the instruments had previously undergone cryogenic testing in a smaller chamber at Goddard.

Engineers from Harris Space and Intelligence Systems, headquartered in Melbourne, Florida, worked alongside NASA personnel for the test at Johnson.

“The Harris team integrated Webb’s 18 mirror segments at Goddard and designed, built, and helped operate the advanced ground support and optical test equipment at Johnson,” said Rob Mitrevski, vice president and general manager of intelligence, surveillance and reconnaissance at Harris. “They were a key, enabling part of the successful Webb telescope testing team.”

The Webb telescope team persisted with the testing even when Hurricane Harvey slammed into the coast of Texas on August 25 as a category 4 hurricane before stalling over eastern Texas and weakening to a tropical storm, where it dropped as much as 50in of rain in and around Houston.

Many Webb telescope team members at Johnson endured the historic storm, working tirelessly through overnight shifts to make sure Webb’s cryogenic testing was not interrupted. In the wake of the storm, some Webb team members, including team members from Harris, volunteered their time to help clean up and repair homes around the city, and distribute food and water to those in need.

“The individuals and organizations that have led us to this most significant milestone represent the very best of the best. Their knowledge, dedication, and execution to successfully complete the testing as planned, even while enduring Hurricane Harvey, cannot be overstated,” said Mark Voyton, James Webb Space Telescope optical telescope element and integrated science instrument manager at Goddard.

“Every team member delivered critical knowledge and insight into the strategic and tactical planning and execution required to complete all of the test objectives, and I am honored to have experienced this phase of our testing with every one of them.”

Over the course of about a week, the air was removed from the chamber before it was cooled. Following which, the chamber, the telescope and the telescope’s science instruments were brought down to cryogenic temperatures over about 30 days. When cooling, Webb and its instruments transferred heat to their surrounding liquid nitrogen and cold gaseous helium shrouds in Chamber A.

Webb remained at “cryo-stable” temperatures for about another 30 days until, on September 27, the engineers began to warm the chamber back to ambient conditions, before pumping the air back into it and unsealing the door.

Inside the chamber Webb was insulated from external visible and infrared light. It was monitored using thermal sensors and specialized camera systems. The thermal sensors kept tabs on the temperature of the telescope, while the camera systems tracked the physical position of Webb to see how its components minutely moved during the cooldown process. Monitoring the telescope throughout the testing required the coordinated effort of every Webb team member at Johnson.

“With an integrated team from all corners of the country, we were able to create deep space in our chamber and confirm that Webb can perform flawlessly as it observes the coldest corners of the universe,” explained Jonathan Homan, project manager for Webb’s cryogenic testing at Johnson.

November 30, 2017