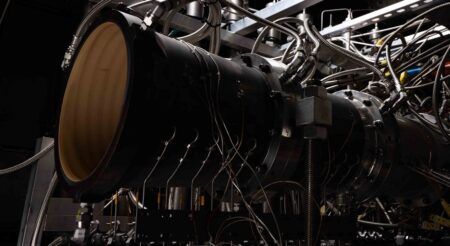

The Rolls-Royce engine is set up in free-jet mode inside the AEDC C-2 test cell at Arnold Air Force Base (U.S. Air Force photo)

Engineers in the USA have set what they say is a new record by achieving transonic speeds with large volumetric flow rates during the free-jet testing of a Rolls-Royce high-bypass engine.

The tests were conducted inside the Arnold Engineering Development Complex C-2 test cell at the US Air Force’s Arnold Air Base during free-jet mode engine testing.

Free-jet testing takes place when an engine is not directly connected to the plenum inside the test cell. Instead, an open nozzle blows air into and around the engine inlet cowling.

In free-jet mode, only 25% or less of the air delivered by the facility is ingested by the engine, the remaining air flows around the engine and through the cell. Free-jet mode requires a massive amount of air from plant machinery to create higher Mach conditions in the cell.

According to Doug Hodges, test engineer with the Propulsion Combined Test Force, free jet testing at C-2 is typically conducted at lower air speeds.

“Reaching a transonic air speed that approaches Mach 1 is not something we normally do when performing free-jet testing for the high-bypass engines,” he said. “Typically the air coming into an engine during a free-jet test is less than .5 Mach.”

When the engine inlet is directly connected to the plenum it receives all the air that is being delivered to the test cell by the plant machinery. Since all the air has to go through the motor, direct connect mode can reach higher Mach numbers more easily than free-jet testing.

Will Perkins, plant operations engineer, said it is more challenging to run in free-jet mode because more plant machinery is required to operate for the higher air flows.

“This condition used all of our air supply machinery and most of the exhaust capability,” Perkins said.

For this test, the C-2 test cell received more than three million cubic-feet of air a minute.

Adam Moon, AEDC test analyst, said, “That’s equivalent to pulling out all the air filling up a warehouse that is 150-feet long, wide and tall every minute, which is significantly more than our average engine test.”

Free-jet testing of large bypass turbofans in the engine test cells at Arnold has been limited to icing testing.

“Previously, these experiments only saw volumetric airflows approaching two million cubic feet per minute, due to the lower Mach numbers. The most recent transonic free-jet testing surpassed 3.2-million cubic feet per minute,” said Moon.

Rolls-Royce has tested several of its engines at Arnold AFB, such as the Rolls-Royce Trent 800 used to power the Boeing 777, the Trent 900 to power the Airbus A380 and the Trent 1000 for the Boeing 787.

Mike Magistro, test operations engineer at the Arnold Air Force Base, said, “A multitude of factors came together to pull this off, but first and foremost was the amount of time, effort and hard-nosed engineering provided from plant and test operations, design, technology, and our Combined Test Force.”

“After that, I’d say it was the test team’s fortitude to hold steady in their seats as we passed Mach 0.80.”

May 23, 2018