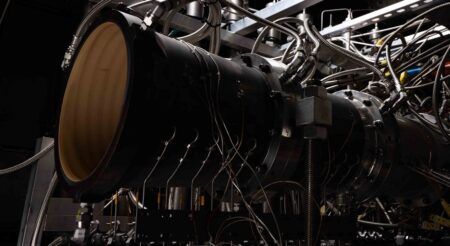

The Rolls-Royce Trent 1000-TEN (Thrust, Efficiency and New Technology) engine was recently tested for performance, operability and icing certification at the Aeropropulsion Systems Test Facility (ASTF) C-2 engine test cell at Arnold Engineering Development Complex (AEDC).

Prior to the end of the test program, Jit Sahota, Rolls-Royce engine owner, stated he was pleased with the effort put forth by Rolls-Royce and AEDC personnel: “So far to date more has been achieved on this engine than any other previous AEDC engine. The team is close to delivering all of the test objectives set and the results thus far are in line with predictions, and in some cases far better than expected.”

Tom Schmidt, ATA project manager, explained some of the objectives for this test: “The first part of the test program verified the expected improvements in thrust and fuel efficiency, operability such as stall margins during fast accelerations and decelerations, plus verifying the start envelopes,” he said.

“The C-2 icing system was then installed to run the prescribed icing condition and to demonstrate the engine’s anti-ice systems and engine ice shedding characteristics.”

Icing tests simulate various flight conditions that the engine may be exposed to during flight. They are required for Federal Aviation Administration and European Aviation Safety Agency certifications.

“These [icing] could occur during an aircraft descent for landing, while in a holding pattern, or while waiting for take-off on a cold, foggy day,” Schmidt said.

During the test, an intensive schedule was implemented to ensure requirements were achieved.

“The test team faced many obstacles to complete this test before a planned summer maintenance outage,” said Melissa Tate, AEDC project manager for the Aeropropulsion Branch. “The team, both AEDC and Rolls-Royce, has triumphed and produced the necessary data to ensure Rolls-Royce can certify the engine and provide their customer with essential information. It took a lot of personnel and many man hours to achieve the test, and everyone involved should be proud. As on past projects, Rolls-Royce and AEDC worked wonderfully together as a single team with a common goal. Testing an engine of this size required the combined support, coordination and accommodation of business areas base-wide.”

This is the third Trent 1000 engine tested at the Complex. During the first test in 2007, the engine was tested for performance, operability and starting before it entered into service on the Boeing 787 Dreamliner in 2011.

Last year, AEDC engineers had another opportunity to perform testing on the engine. “We tested an improved version of the Trent 1000 to verify the performance enhancements provided by the Package C upgrades,” Schmidt said.

In part, because of the successful testing performed on the Trent 1000 at AEDC, Rolls-Royce now has a single engine that will power all variants of the Boeing 787 Dreamliner. Currently, there are 450 Trent 1000-powered Boeing 787 Dreamliners ordered by 27 different customers around the world.

“Overall this was a fantastically successful test program,” Schmidt said. “It took the combined efforts of literally hundreds of people to produce this test program.

Sahota agreed that the success of the test was “a tremendous team effort from AEDC and Rolls-Royce teams. Many thanks to all involved.”