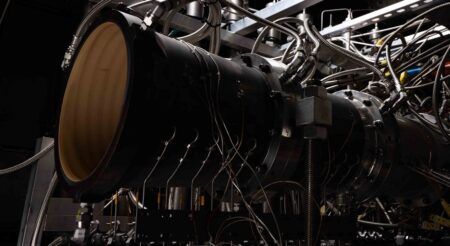

A series of static test firings of a prototype tactical solid rocket motor have been completed successfully by Orbital ATK. The motor included a rocket nozzle and closure assembly fabricated by additive manufacturing (3D printing). This is the first time such critical and complex metal components have been included in a tactical class rocket motor.

The assembly and testing of the motor, developed in partnership with the US Army Aviation and Missile Research, Development and Engineering Center (AMRDEC), was conducted at Orbital ATK’s Tactical Propulsion and Ordnance facility in Rocket Center, West Virginia.

The prototype boost motors featured a high-strength graphite epoxy composite case, a reduced sensitivity minimum signature rocket propellant, and 3D printed components.

The company revealed that the test firings successfully validated the boost motor and component performance across the full operational temperature range from -26° to +145°F, closely matching pre-test predictions and meeting all test objectives.

The 3D-printed single-piece high-strength steel rocket nozzle and closure structure is expected to improve system affordability by significantly reducing parts count and manufacturing complexity of the current fielded system. The perforated rocket motor igniter housing and nozzle weather-seal used in the prototype tests were also additively manufactured.

“Orbital ATK has been very successful in taking additive manufacturing out of the academic world and incorporating it into our industrial design and operations,” said Pat Nolan, vice president and general manager for Orbital ATK’s Missile Products Division, part of the Defense Systems Group.

“Our goal is not just to create industry firsts, but to create practical, reliable solutions that increase our products’ effectiveness while reducing the time it takes to get them into the field.”

November 2, 2017