Orbital, along with NASA and Lockheed Martin, successfully performed a ground firing test of the abort motor for NASA’s Orion spacecraft Launch Abort System (LAS) at Orbital ATK’s facility in Promontory, Utah.

The launch abort motor is a major part of the LAS, which provides a tremendous enhancement in spaceflight safety for astronauts.

“We at Orbital ATK are very proud to work with NASA and Lockheed Martin on the Orion Launch Abort System, and to provide a motor that is so integral to astronaut safety,” said Charlie Precourt, vice president and general manager of Orbital ATK’s Propulsion Systems division and former NASA astronaut. “The importance of our crews’ safety and well-being can’t be stressed enough.”

The mission for Orion’s LAS is to safely jettison the spacecraft and crew out of harm’s way in the event of an emergency on the launch pad or during initial launch ascent. Today’s abort motor test, Qualification Motor-1 (QM-1), was the culmination of a series of component tests conducted over the past few years in preparation for qualification. The test will confirm the motor can activate within milliseconds and will perform as designed under high temperatures.

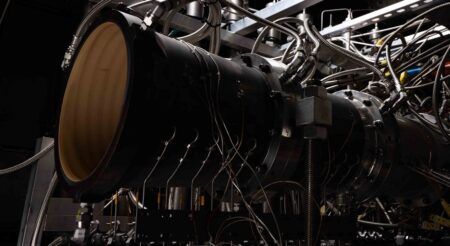

The abort motor, which stands over 17ft (5m) tall and spans 3ft (0.9m) in diameter, has a manifold with four exhaust nozzles. It was fixed into a vertical test stand with its nozzles pointing skyward. Upon ignition, the abort motor fired for five seconds with the exhaust plume flames reaching up to 100ft (30.5m) in height.

The high-impulse motor was specifically developed so the majority of its propellant would be expended in the first three seconds, burning three times faster than a typical motor of this size and delivering the thrust needed to pull the crew module safely away from its launch vehicle. The motor reached 400,000 lb (1,779kN) of thrust in one eighth of a second, as expected. This is enough thrust to lift 66 large SUVs off the ground.

This milestone brings Orion one step closer to its first flight atop NASA’s Space Launch System, Exploration Mission-1, and to eventually enabling humans to explore beyond the Moon, Mars and other destinations beyond low Earth orbit. More analysis will be performed in the coming weeks, but all initial test results appear to be nominal.

Orbital ATK’s next major abort motor milestones include the QM-2 launch abort motor test firing scheduled for late next year in Utah, and the Ascent Abort-2 Flight Test (AA-2) scheduled to take place at Cape Canaveral Air Force Station, Florida, in 2019. Previous large-scale tests of the launch abort motor include a development motor test in 2008 and a test of the complete LAS in 2010.

Orbital ATK is responsible for the launch abort motor through a contract to Lockheed Martin – Orion’s prime contractor. The Orion LAS program is managed out of NASA’s Langley Research Center in Virginia. Orbital ATK produces the abort motor at its Magna, Utah, facility and the attitude control motor at its Elkton, Maryland, facility. The company also manufactures the composite case for the abort motor at its facility in Clearfield, Utah.

June 21, 2017