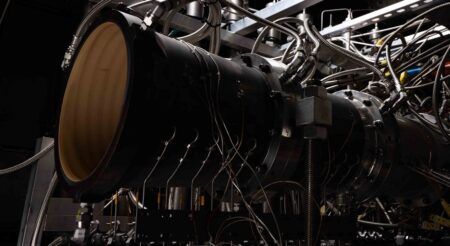

GE Aviation has successfully completed the first test run of its Advanced Turboprop engine, which uses more 3D-printed parts that any production engine ever developed.

Some 35% of the Advanced Turboprop’s (ATP) parts have been produced using additive manufacturing. The ATP is also the first clean-sheet engine developed for the business and general aviation (BGA) market for more than 30 years.

The first run of the Advanced Turboprop was conducted at its facility in Prague, Czech Republic, last month.

Brad Mottier, vice president and general manager of GE Aviation’s BGA and Integrated Systems division said, “This milestone comes as a result of two years of tremendous effort by a worldwide team. We’re developing a real catalyst for the BGA market and we’re executing on plan. The integration of proven technologies has expedited the design, development and certification cycle of the engine.”

The Advanced Turboprop engine will begin certification testing in 2018. The engine will power Textron Aviation’s new Cessna Denali, which is expected to fly in late 2018. By the time the Denali enters service, the engine will have completed more than 2000 hours of testing.

“The continued testing will generate valuable data from the engine and validate the aerodynamics, mechanics, and aerothermal systems,” said Paul Corkery, general manager for GE Aviation Turboprops.

“With the engine run and most of the individual component testing completed, early indications show that we will meet or exceed all the performance numbers we have quoted for the engine.”

Engineers successfully reduced 855 conventionally manufactured parts to 12 additive parts during the development of the ATP.

Conventionally-manufactured parts, which are now produced using additive manufacturing, include sumps, bearing housings, frames, the exhaust case, the combustor liner, heat exchangers and stationary flow path components.

The use of additive components has reduced the ATP’s weight by 5% while contributing to a 1% improvement in specific fuel consumption (SFC).

The 1,240shp-rated Advanced Turboprop engine is in the family of turboprop engines aimed at BGA aircraft. According to GE Aviation, the engine features a 16:1 overall pressure ratio, enabling the engine to achieve as much as 20% lower fuel burn and 10% higher cruise power compared to competitor offerings in the same size class. At 4,000 hours, it offers 33% more time between overhaul than its leading competitor.

January 10, 2018