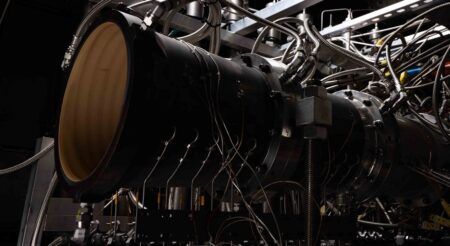

GE Aviation has begun testing the first full engine in the Future Affordable Turbine Engine (FATE) program under a cooperative agreement between GE and the US Army. The engine is designed to meet a series of aggressive goals including a 35% reduction in specific fuel consumption, an 80% improvement in power-to-weight, a 20% improvement in design life, and a 45% reduction in production and maintenance costs relative to currently fielded engines. The increases in engine capabilities provide a significant contribution to increasing hot-and-high payload and performance and extended range and endurance for either upgrades to existing aircraft or new rotorcraft.

The first full engine test follows the successful completion of FATE compressor, combustor and turbine rig tests in 2015. The FATE compressor rig recorded the highest single-spool compressor pressure ratio in GE Aviation’s history. The combustor test incorporated extensive use of ceramic matrix composites (CMCs) in the combustor. The CMC material provides high-temperature capability and weight reduction for better performance. The FATE turbine rig was built using additive manufacturing techniques for faster construction and lower development costs. These rigs followed FATE inlet particle separator tests completed in 2014.

“The FATE program is the most advanced turboshaft development program in GE’s history, incorporating an extensive use of state-of-the-art technologies for the next generation of propulsion,” said Harry Nahatis, GE Aviation’s general manager of Advanced Turboshaft Programs. “We’re proud to work with the Army in maturing these breakthrough technologies and we’re very encouraged with the full engine test results thus far.”

In 2011, GE was competitively awarded the FATE cooperative program to design a 5,000-10,000shp-class turboshaft engine that demonstrates technologies applicable to existing aircraft and future rotorcraft requirements such as the US Department of Defense’s Future Vertical Lift (FVL) program.

Likewise, these technologies can be incorporated into new engines including the GE3000, which was demonstrated in the Army’s Advanced Affordable Turbine Engine program, and GE has offered for the ITEP program, or upgrades to existing engines such as the ubiquitous T700, which powers several medium-lift helicopters including the Black Hawk and Apache, and the T408 engine, which powers the US Marine Corps CH-53K heavy-lift helicopter.

“Between the T408, GE3000 and FATE programs, we have a unique multigenerational product plan that shares technologies across our military rotorcraft efforts, incorporates commercial engine technologies and fuses them together in a low-risk manner to drive high-performance and affordable engines applicable to both military and commercial aircraft,” said Jean Lydon-Rodgers, VP and general manager of GE Aviation’s Military Systems Operation.

14 October 2016