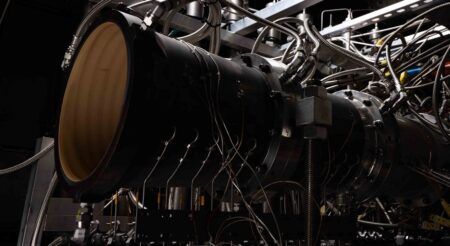

Turbofan jet engine

Ceramics played a vital role in the manufacturing of the hollow turbine blades for China’s first jet engine.

Ceramic cores supplied by Morgan Advanced Materials’ Technical Ceramics Business were used to create the hollow turbine blades used in the CJ-1000A engine.

The CJ-1000A, the first jet engine produced in China, will be used to power the country’s first passenger jet, the COMAC C919, which is due to be rolled out from 2020. The new engine replaces the imported engines which were used during the aeroplane’s development.

The engine design uses hollow turbine blades and vanes to reduce overall weight and provide internal cooling passages to prevent the blades overheating when in use. To make sufficiently light weight and robust hollow blades, ceramic cores are placed in the center of the mold during casting of the components.

Morgan Advanced Materials was commissioned to create these ceramic cores at its ceramic core manufacturing facility in Wuxi, Jiangsu province, in eastern China.

Engineers from Morgan worked with the engine manufacturers and designers to achieve the exact dimensions required for the internal cooling passages. The cores are manufactured in heat-resistant materials that can withstand the casting process without compromising the integrity of each blade’s super-alloy construction. Once cast, the ceramic core is leached out to leave the blade hollow.

Morgan has supplied four core designs to support the casting of stage 1 and 2 blades and vanes. To date, over 1000 individual cores have been manufactured. These numbers will rise significantly when the aircraft enters mass production, as 600 engines per annum will be required to meet the forecasted annual target of 150 aircraft.

Raymond Gao, general manager of Morgan’s Ceramic Core Technology facility, which has manufactured the components for the project, said, “This is a groundbreaking project for the Chinese aerospace industry and we’re delighted to play such an important part in getting this pioneering engine into production.

“It’s also a great example of how Morgan can provide customers with a combination of global expertise and local support, to deliver advanced materials that help manufacturers to push back the boundaries of what they can achieve.”

March 16, 2018