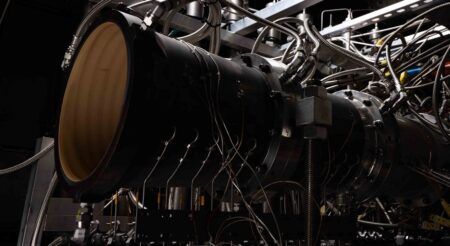

New Zealand-based Aurora Labs has met targets for weight reduction and improved performance in its 3D printed 200N Class micro gas turbine.

The micro gas turbine is suitable for use in small, lightweight propulsion systems or power plants in drones and similarly sized air vehicles.

The company is releasing the 200N model to the market next month with capabilities for lightweight propulsion systems in a broad range of markets. In parallel the development of a 400N Class model is progressing.

Aurora Labs (A3D) has manufactured the product in under four months using its 3D printer.

CEO of A3D Rebekah Letheby said, “3D metal printing has worked to its strength in accelerating the product prototyping process of our sovereign turbine engine. The turbine engine design and printing have met benchmarks for laboratory prototype testing. Testing will now move to the field where the engine can be fitted to a remotely piloted airframe.

“We have an excellent level of interest in our printed engines which have applications in unmanned aerial vehicles and instant power generation.”

Weight reduction

A3D said it had met the targets for required thrust, air intake efficiencies, engine weight and fuel consumption constraints have been met, and that it has scope for more improvements through generative design changes that are made possible using 3D printing.

It added that the engine operates and compares in function and performance requirements to comparable engines built by traditional manufacturing methods. However, it has fewer complex parts, resulting in a faster and more reliable assembly process.

A3D’s testing focus was on efficiency and the weight of turbines. Individual parts have been lightweighted to improve fuel efficiency and some parts have been amalgamated and printed as one assembly.

In one section of the engine, engineers took 18 parts and amalgamated them into just 1 printed part, while realizing a 20% weight reduction on traditional engines of the same class.

Testing has shown that the printed interior components can withstand the stress and high temperatures experienced during the firing of the engine. The printed material is comparable to conventional metal materials which gives assurance to users that the end quality of the metal product is reliable and repeatable with the A3D printing method.

The turbine can run on Jet-A1, kerosene and diesel fuels.

Industry Engagement

A3D plans to supply data from the the testing to several prospective customers with requirements for gas turbine systems in various applications, including propulsion for drones. The company is working with several customers who have already seen the capabilities of the gas turbine engine while in testing.

In parallel with testing of the 200N class model, the company is fast tracking the design and build of a larger 400N Class gas turbine for large scale applications in drones where small turbines can be used as propulsion systems. In parallel, the Company continues to work towards delivery of the first AL250 printer.