In November 2023, UK regulator the Civil Aviation Authority launched its Hydrogen Challenge. The aim is to investigate hydrogen as a zero-carbon emission aviation fuel, looking at a powertrain and fuel system, airport storage and fueling infrastructure and regulation.

In February 2024, Cranfield Aerospace Solutions (CAeS), Exeter Airport Consortium and ZeroAvia became the first companies selected to work alongside the CAA in its so-called Hydrogen Sandbox Challenge.

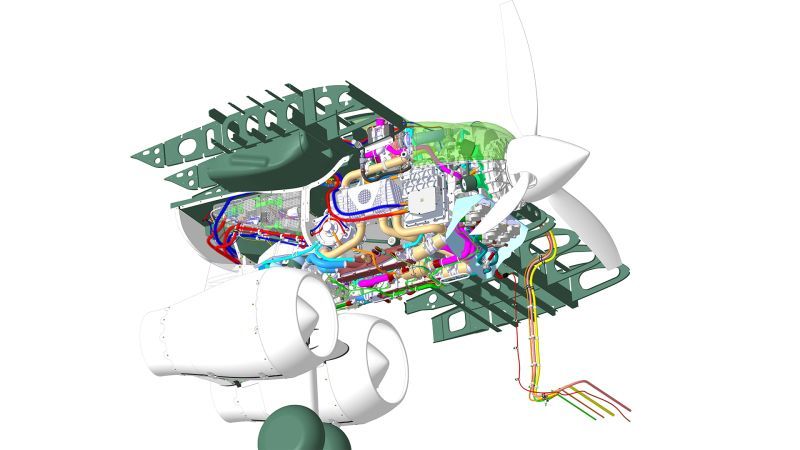

CAeS is developing a hydrogen fuel cell powertrain under Project Fresson. The initial work aims to engineer, flight test and prove a powertrain suitable for the Britten-Norman Islander and, in a break from the norm it has chosen the target platform as a flight test vehicle. Design, airframe modification and flying are centred at the company’s base on the Cranfield University Centre for Aeronautics campus in Bedfordshire, UK.

Established in 1945, Cranfield College of Aeronautics soon developed a design organization. Spun off as Cranfield Aerospace Limited in 1997, it was rebranded as Cranfield Aerospace Solutions in 2016. The CAeS offices are a five-minute walk from its hangar. Under modification inside, 1995-vintage BN-2B-26 Islander G-HYUK (‘UK) is no stranger to the limelight – under previous ownership it was seriously abused by 007 in the 2015 movie Spectre.

Engineering & flying

Daqing Yang is principal air vehicle design engineer at CAeS. A Cranfield graduate, his background is in commercial aircraft prototype design and research. For Project Fresson his team is replacing one of the relatively small aircraft’s engines with all-new technology. New engines are typically not trialed on the platform for which they are intended, but that is not the case with Project Fresson.

“We have seen hydrogen powertrains flown, but not as potential powerplants for the platform they’ve flown on – they’ve been much smaller,” Yang says. “We have a hydrogen fuel cell powerplant tailor-made for the Islander category of aircraft. Powering the Islander is well within its capability, so when we’ve successfully tested it we’ll be much closer to a viable market product.”

Project Fresson chief test pilot (CTP), Roger ‘Dodge’ Bailey, has flown the unmodified ’UK extensively. A former Royal Air Force Hercules pilot, Dodge was a flying instructor before training at the US Air Force Test Pilot School. Back in the UK, he flew with the Royal Aircraft Establishment at Bedford, before joining Cranfield College of Aeronautics as CTP in 1990. Bailey led the National Flying Laboratory Centre before semi-retiring in the mid-1990s, after which he continued as CTP on a part-time basis; Bailey brings more than three decades of test flying experience in Bedfordshire skies to Project Fresson.

Preparations for the hydrogen-electric powertrain installation were well advanced in mid-2024, by which time Bailey and flight test observers had gathered a baseline set of data on the aircraft’s flying characteristics and performance. “The Islander is a proven aircraft that I’d flown in the past. It’s not fast, but it does the job. There’s not a lot of new ground to be broken in terms of the aircraft, but if the project goes all the way to a certified hydrogen-powered Islander then there will be the need for a training package, for example.

“Since there are no Islander simulators, some of the testing we’ve done and continue to do is to validate an Islander flight model for a simulator.”

Working closely with Yang, Alexander Purvis is a CAeS air vehicle design engineer. Another Cranfield graduate, Purvis nods towards Yang while describing himself as “much less senior, I graduated in 2022”. Purvis has been involved in a good deal of the flight testing, sitting alongside Bailey as he manoeuvres the Islander. “Some of the tests we have flown have been about assessing our Islander. The basic design is 60 years old, and our aircraft is almost 30 years old. We expect some degradation, not so much to the airframe but the engines,” he says.

Given its age and the handmade nature of the Islander compared to modern platforms, Yang says detail discrepancies in ’UK’s construction compared to the manual have already emerged. “Luckily,” he notes, “Cranfield Aerospace Solutions also specializes in repair, overhaul and modification, so we’re used to mitigating these sorts of problems.” Finding solutions to issues as simple as discovering a fixing hole drilled a few millimeters away from where it was expected requires close cooperation between Yang’s team and the engineers on the tools in the hangar.

“We work closely with our dedicated mechanical and structural teams,” Yang adds, noting that Purvis, for example, works closely on the aircraft’s mass and balance, which means visiting the hangar to weigh and record all aircraft components, then keeping track as modifications are added to monitor weight.

Bailey says the focus for testing ’UK is all powerplant related. “There’s a lot of it,” he continues. “We’re installing the new powertrain on one side and its size, weight, drag and thrust are all different. The baseline testing established the performance of our aircraft; like many light twins, the Islander’s engine-out performance on take-off is not brilliant, so we needed to know what we had. We’re keeping a Lycoming piston engine on the left side, but testing shows our right-hand engine is the better one, so we’ll swap it for the left one before flying again with the electric motor on the right.

“Some baseline testing also reflects something I always did when I worked for the university full time. If you modified a certified aeroplane it becomes uncertified, and then you want to certify it again. But you don’t know how it got through the original certification process, and you don’t want to modify it and then find out it doesn’t comply with a requirement it should have complied with, because you won’t know if it never did or if the modification is responsible.”

Bailey believes the most important certification performance data are on climb and single-engine climb performance, both of which have safety implications. He adds, “Those parameters are associated with best speeds, and these bring in aspects including minimum control speed with one engine inoperative, which is on the boundary between performance and handling qualities.

“The latter are primarily about stability and control. The aircraft was certified against a certain amount of longitudinal and directional stability and so on, and we’ve tested against those. Most handling qualities certifications are primarily qualitative; the requirement will say ‘if you sideslip the aeroplane it must respond this way’, it won’t say ‘…must respond at X° per second’.”

Although there is not yet a simulator suitable for line pilot training, CAeS has developed a desktop simulator that has a variety of uses.

“One of the mitigations for flight testing with an experimental engine on one side of the Islander answers the question of what happens if it stops during take-off. In keeping with most light twins, the Islander has an area of vulnerability where if an engine fails on take-off you have to put it down again,” Bailey says.

“To mitigate that risk we want to be able to do that at Cranfield – get to a height at which we can land back on the runway or continue on one engine. We can practise that profile on the desktop simulator and flight test profiles too, assessing how long they might take and what that means in terms of hydrogen consumption.”

(Image: Cranfield Aerospace Solutions)

Before flight

An extensive period of ground trials is planned once the hydrogen powertrain has been installed and Bailey expects to have some involvement in them. “As soon as its representative of the configuration we will go and fly, I want to be there. I won’t fly the aeroplane unless I’ve operated the engine a good deal beforehand.”

Lengthy trials will also have taken place in the virtual world before first flight, meaning Yang is confident the hydrogen fuel cell will deliver in the air. A mathematical model describing the aircraft’s dynamics with Lycoming engines and constant-speed propellers has already been constructed and work continues on the hydrogen fuel cell model. “The fuel cell powerplant is a little more powerful than the Lycoming, so we’re using a slightly larger propeller and different governor, and those elements are all being built up in the model from a clean sheet,” Yang explains. The result is a ‘digital Islander’, which Yang says will be modified according to data gathered during flight trials.

Each test sortie will have a pilot and flight test observer and the aircraft will carry ballast fuel on its left side to balance the greater weight of the hydrogen installation to starboard. The Islander has already been instrumented, as Purvis explains. “Rather than an integrated inertial management unit in the baseline, we used an array of smart phones connected to MATLAB to record the flights, with date stamps on individual tests.” “We trialed our solution on the National Flying Laboratory Centre Saab 340B and compared the results, giving us confidence in our data,” Yang adds. Also proven on the Saab, CAeS will use a data recording system for the hydrogen trials.

Aside from the aircraft and its powerplant, another fundamental challenge remains to be addressed. If CAeS was testing a new jet engine, the supporting infrastructure around safely refueling it would require little thought. That is not the case for fueling a hydrogen fuel cell. Yang continues, “We have a dedicated safety team that talks to the CAA, which is also on the same learning curve. They are keen to observe our best practice to help write future regulations, but for now, we are working towards permission for experimental flying.”

Yang says a major challenge comes from cooling the hydrogen fuel cells without adding excess drag. In the initial installation the hydrogen tanks will go inside the fuselage, since prominent heat exchangers will hang under the right engine nacelle. That solution is not viable for a commercial product, where cabin volume will be required for payload. The hydrogen tanks will therefore go under the wings. The Islander already has provision for underwing hardpoints.

Yang is also interested in those Islander models built with wingtip fuel tanks, where he says the reinforced structure offers the potential for hydrogen carriage. “The wing structure redesign would be minimal, but we’d still need to check stress and the aeroelastic impact on the aircraft,” he adds. The digital model means much of the work can be done on-screen.

Certification testing

Trials with the fully modified, all-hydrogen aircraft will aim to gather data towards certification as well as pure test. In that phase, Bailey notes one of many questions related to electric flying: “We’ll need climb, twin-engine and single-engine performance data and, particularly, landing performance data. Landing performance is among the challenges of electric motors. When the fuel supply to a piston engine is reduced, the airflow keeps the airscrew turning, in a way running the engine backwards. Keeping the engine turning this way requires considerable energy, creating ‘windmilling drag’ which is very useful during a steep approach into a short airfield.

(Image: Cranfield Aerospace Solutions)

“Islanders do a lot of steep approaches into short airfields, but when you ‘back-drive’ an electric motor by reducing power the effect isn’t the same. There’s a bit of an unknown around how that will work, and part of the technology might be designing something to replace windmilling drag.

“As a test pilot,” he concludes, “Overall, I’m more concerned with where the power is coming from, because electric motors are pretty much bombproof. The propeller will be fine but may not be the best solution long term.

“Meanwhile, aeroengines are configured to keep going if there is a failure, giving the pilot the choice of continuing to an airfield to save the aeroplane at the expense of wrecking the engine. Electric powertrains as we’ve seen them in cars tend to protect themselves if there is a failure and we need to see how that philosophy changes in the air.”

Neither test pilot nor engineers are keen to predict a detailed timeline for the program, but first flight with the single hydrogen powertrain is anticipated for 2025, while a seemingly very optimistic further aim is for market entry of a certified commercial product from 2027.

Yang says flying the converted Islander will be a dream come true, while Purvis is perhaps an excellent example of the young engineers who will see hydrogen fuel cell and other new-generation aircraft propulsion systems into service as aviation closes on its promised 2050 net-zero deadline. He describes Project Fresson as “incredibly exciting”, especially taking a role in test flying and having the engineering design office, all the people involved in the project, and the aircraft and hangar altogether on campus.